Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

In the rapidly evolving landscape of manufacturing and product design, the selection of the right materials can significantly impact performance and user satisfaction. Adhesive Rubber Feet have emerged as essential components for a variety of applications, providing stability, vibration dampening, and surface protection. According to a recent industry report by MarketsandMarkets, the global market for rubber products is projected to reach $50 billion by 2025, highlighting the growing demand for specialized materials such as adhesive rubber feet in various sectors.

Experts in the field emphasize the importance of choosing the right adhesive rubber feet for specific projects. Dr. Emily Johnson, a well-regarded materials engineer, states, “The quality and suitability of adhesive rubber feet can make or break the functionality of a product. It’s crucial to assess factors such as adhesion strength, temperature resistance, and surface compatibility.” As designers and engineers strive for innovation and efficiency, understanding the nuances of adhesive rubber feet will be paramount in crafting products that not only meet but exceed quality expectations. This guide aims to provide insights and criteria for selecting the best adhesive rubber feet, ensuring your projects are equipped with reliable and effective solutions.

When selecting adhesive rubber feet for your projects in 2025, it's crucial to understand the various types available on the market. The most common types include silicone, neoprene, and polyurethane rubber feet, each offering distinct properties suited to different applications. For instance, silicone rubber feet are known for their excellent temperature resistance and flexibility, making them ideal for projects exposed to fluctuating heat levels. On the other hand, neoprene rubber feet offer great oil and weather resistance, which is beneficial for outdoor or industrial settings.

Another critical factor to consider is the adhesive backing. Depending on your project needs, you can choose between permanent and removable adhesives. Permanent adhesives provide strong bonding for long-term applications, ensuring that the rubber feet stay securely in place. Removable adhesives, however, allow for repositioning without damage, making them suitable for temporary setups or prototypes. Understanding these differences will help you choose the right adhesive rubber feet that not only meet your project's functional requirements but also enhance durability and performance.

When selecting adhesive rubber feet for your projects, several key factors should guide your decision-making process. The type of surface the adhesive will be applied to is crucial, as some adhesives bond better to smooth surfaces like metal or glass, while others are designed for porous materials such as wood or fabric. Additionally, consider the weight and type of object that the feet will be supporting. Heavier items require rubber feet with a higher load capacity and better adhesion properties to prevent slipping or damage.

Another important factor is the environmental conditions the adhesive rubber feet will be exposed to. Factors such as temperature fluctuations, humidity, and exposure to chemicals can greatly affect the performance of adhesive feet. Ensuring you select materials that can withstand the specific conditions of your project will enhance the durability and longevity of the feet. Finally, consider the hardness and anti-slip properties of the rubber itself; softer rubber may provide better grip while harder rubber could offer more durability. By carefully evaluating these aspects, you can choose the best adhesive rubber feet to suit your project's needs.

This bar chart illustrates the key factors to consider when selecting adhesive rubber feet for projects, along with their importance ratings. The ratings reflect how crucial each factor is in terms of functionality and performance.

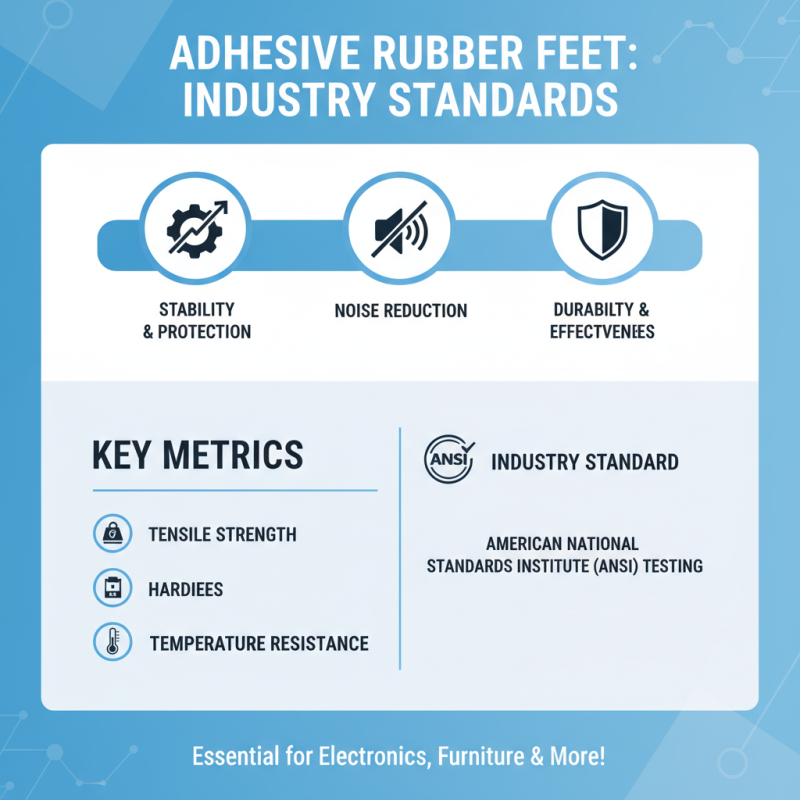

Adhesive rubber feet are essential components in various industries, from electronics to furniture, providing stability, protection, and noise reduction. When selecting the best adhesive rubber feet for your projects, it is crucial to consider industry standards and performance metrics that ensure they will meet specific application needs. According to the American National Standards Institute (ANSI), the testing for rubber feet typically involves evaluating factors like tensile strength, hardness, and temperature resistance, which can significantly influence the durability and effectiveness of the product in real-world scenarios.

Performance metrics such as Shore A hardness, measured on a scale from 0 to 100, indicate the hardness of rubber materials, with lower values representing softer compounds that can provide better grip and cushioning. Additionally, the ASTM D412 standard outlines the tensile and elongation properties that rubber feet should meet, with a minimum tensile strength of 1,000 psi being recommended for reliable performance in various conditions. By choosing adhesive rubber feet that adhere to these standards, you can ensure that they will not only enhance product stability but also withstand wear and tear over time.

**Tips:** When selecting adhesive rubber feet, perform a thorough examination of the environmental conditions they will face. Opt for rubber materials specifically formulated for high-temperature or moisture-prone applications if necessary. Additionally, pay attention to the adhesive type, as certain formulations will provide better bonding on different surfaces, ensuring reliability in your final product.

Adhesive rubber feet have become an essential component in various industries, providing stability, protection, and functionality in a wide range of applications. In the electronics sector, for instance, these rubber feet are utilized to prevent devices from sliding or scratching surfaces, as well as to reduce noise and vibrations during operation. The cushioning effect of adhesive rubber feet enhances the durability of electronics by protecting them from impact and wear, which is particularly important for maintaining the integrity of sensitive components.

In the furniture industry, adhesive rubber feet serve a crucial role in safeguarding floors from scratches and dents caused by movement. They provide a sturdy grip that prevents furniture from slipping and helps maintain the alignment of pieces. Additionally, these rubber feet come in various shapes and sizes, making them versatile for different types of furniture, from office chairs to kitchen appliances. The ease of application and removal allows for practical adjustments and replacements as needed, further contributing to their widespread use across various sectors.

| Industry | Application | Benefits | Material Type |

|---|---|---|---|

| Electronics | Secure placement of devices | Vibration dampening, non-slip | Silicone rubber |

| Furniture | Chair and table legs protection | Floor protection, sound absorption | EPDM rubber |

| Automotive | Soundproofing and vibration control | Improved ride quality, durability | Natural rubber |

| Medical | Equipment stability | Safety, sterility | Polyurethane |

| Construction | Prevent sliding of heavy equipment | Increased safety, equipment longevity | Neoprene |

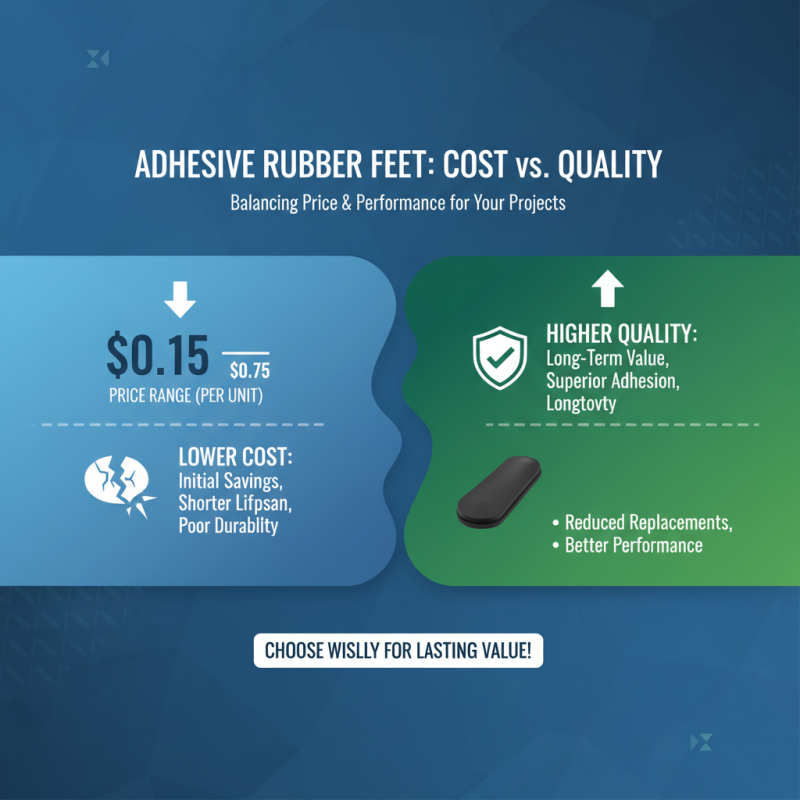

When selecting adhesive rubber feet for your projects, understanding the balance of cost and quality among leading brands is crucial. A recent industry report highlighted that the average price range for adhesive rubber feet can vary significantly, from $0.15 to $0.75 per unit, depending on the materials used and the production processes involved. While lower-priced options may save initial costs, they often compromise durability and performance. In contrast, investing in higher-quality options could lead to better long-term value, as they typically exhibit superior adhesion and longevity, reducing the need for frequent replacements.

**Tip:** Consider conducting a test with different brands before making a bulk purchase. This approach will allow you to assess the adhesion strength, quality of materials, and overall performance directly.

Furthermore, it's essential to look for certifications indicating adherence to safety and quality standards, as many consumers prioritize environmentally friendly materials. Industry analysis suggests that products with such certifications not only provide better performance but also resonate with eco-conscious customers. By choosing adhesive rubber feet backed by recognized testing, you can ensure that your projects benefit from both high performance and consumer trust.

**Tip:** Always review user testimonials and expert reviews to gain insights into the real-world performance of adhesive rubber feet products.