Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

The bespoke rubber moulding industry is poised for transformative growth, with emerging trends set to shape the landscape of custom manufacturing solutions by 2025. As industries increasingly seek personalized and high-performance components, the demand for bespoke rubber moulding—tailored specifically to meet unique specifications—is on the rise. A recent report by Smithers revealed that the global market for advanced rubber moulding technologies is expected to reach $10 billion by 2025, driven by innovations in materials and production techniques.

According to industry expert Dr. Robert Jennings, "The future of bespoke rubber moulding lies in our ability to integrate cutting-edge technology with traditional craftsmanship, ensuring that custom solutions are not only efficient but also deliver unparalleled performance." This perspective highlights the critical intersection of innovation and customization in meeting the diverse needs of applications across sectors such as automotive, aerospace, and medical devices. As we delve into the top trends that will define the bespoke rubber moulding sector in the years to come, it is essential to consider how these advancements will influence manufacturing practices, sustainability, and product performance.

The landscape of bespoke rubber moulding is rapidly evolving, driven by advancements in technology and the increasing demand for customized manufacturing solutions. According to a recent industry report by Grand View Research, the global rubber molding market is projected to reach over $20 billion by 2025, fueled by innovations in production processes and material science. Emerging technologies, such as 3D printing and automation, are expected to play pivotal roles in enhancing the precision and efficiency of custom rubber components.

In 2025, the integration of digital manufacturing techniques, including computer-aided design (CAD) and simulation software, will enable manufacturers to create complex rubber molds with greater accuracy and reduced lead times. A study from the International Journal of Advanced Manufacturing Technology highlights that the adoption of smart manufacturing technologies can enhance production efficiency by up to 30%. Furthermore, advancements in eco-friendly materials, such as bio-based elastomers, are gaining traction, aligning with global sustainability goals and consumer preferences for greener products.

Another key trend shaping the bespoke rubber moulding industry is the rise of Industry 4.0. The utilization of the Internet of Things (IoT) in manufacturing processes allows for real-time data collection and analysis, leading to improved quality control and waste reduction. A report by McKinsey anticipates that IoT applications in manufacturing could create value of $1.2 trillion to $3.7 trillion annually by 2025. As manufacturers embrace these innovative technologies, they will not only enhance their operational capabilities but also meet the increasingly specific demands of their customers, driving the growth of bespoke rubber moulding solutions.

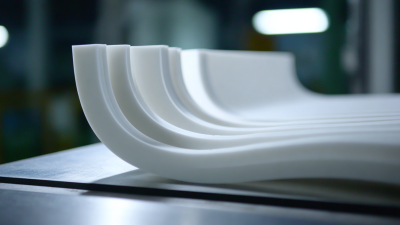

The landscape of bespoke rubber moulding is continuously evolving, driven by innovative materials that enhance the potential for custom manufacturing solutions. With advancements in polymer science, manufacturers are now able to employ a variety of materials that cater to specific performance requirements. For instance, according to a report by Research and Markets, the global rubber market is projected to grow by over 5% annually through 2025, with a significant portion attributed to the demand for high-performance materials tailored for unique applications.

One notable trend is the increasing use of thermoplastic elastomers (TPEs) which combine the best features of rubber and plastic. TPEs offer flexibility, durability, and recyclability, making them an attractive option for manufacturers looking to implement sustainable practices. Additionally, the ability to produce custom formulations allows for enhanced properties such as resistance to extreme temperatures or chemicals. Notably, a study from Smithers Pira highlights that custom rubber moulding driven by these innovative materials is anticipated to occupy a larger share of the market, as companies seek to differentiate their products in increasingly competitive sectors.

Moreover, the integration of smart materials into bespoke moulding processes is gaining traction. Materials embedded with sensors or responsive elements can lead to the creation of components that not only fulfill traditional roles but also react dynamically to their environment. The global market for smart materials is expected to exceed $80 billion by 2025, indicating a substantial opportunity for custom manufacturers to leverage these technologies in their product offerings, enhancing performance and functionality in a variety of applications.

As the demand for custom manufacturing solutions continues to grow, the rubber moulding industry is witnessing a significant shift towards sustainability. In 2025, a major trend is the incorporation of eco-friendly materials and practices into bespoke rubber moulding. According to a recent McKinsey report, sustainable manufacturing can lead to increased efficiency and reduced costs, with companies witnessing a decrease in operational expenses by up to 20% when they adopt green practices.

One of the most transformative practices emerging in bespoke rubber moulding is the use of bio-based and recycled materials. A study by the Ellen MacArthur Foundation indicates that adopting circular economy principles can create an annual economic benefit of $630 billion across the global rubber industry by 2030. This transition not only helps companies meet regulatory requirements but also appeals to the growing consumer base that prioritizes sustainability. Manufacturers are increasingly sourcing materials from recycled rubber and bio-based polymers, which significantly reduce environmental impact compared to traditional synthetic rubbers.

Furthermore, advancements in manufacturing technologies, such as additive manufacturing and smart moulding processes, are enabling more efficient production cycles while minimizing waste. Industry experts project that implementing these innovations can reduce material waste by over 30%, enhancing overall sustainability efforts. As bespoke rubber moulding continues to evolve, the focus on sustainability will remain paramount, driving the industry towards a greener future.

| Trend | Description | Sustainability Impact | Implementation Year |

|---|---|---|---|

| Recycled Rubber Materials | Utilizing recycled rubber in moulding processes for eco-friendly products. | Reduces landfill waste and lowers carbon footprint. | 2025 |

| Biodegradable Compounds | Development of rubber compounds that break down naturally over time. | Minimizes long-term environmental impact. | 2025 |

| Energy-Efficient Production | Adopting energy-saving technologies in the manufacturing process. | Reduces overall energy consumption and emissions. | 2025 |

| Smart Manufacturing Integration | Incorporating IoT and AI for efficient manufacturing planning. | Enhances resource management and reduces waste. | 2025 |

| Customisation Options | Offering more bespoke solutions tailored to client needs. | Promotes sustainability through precise consumption and reduced overproduction. | 2025 |

The landscape of custom rubber solutions is evolving rapidly, driven by shifting market demands and technological advancements. According to a report by MarketsandMarkets, the global rubber moldings market is expected to reach $27.7 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.2%. This growth is fueled by the increasing need for precision-engineered products across various sectors, such as automotive, aerospace, and medical industries. The rise in automation and customization in manufacturing processes highlights the necessity for bespoke rubber moulding solutions that can meet specific client requirements for durability, flexibility, and compliance with stringent industry standards.

Industry analyses indicate that there is a growing trend towards sustainability in manufacturing, with many organizations seeking eco-friendly materials without compromising on performance. The use of reclaimed rubber and bio-based materials is gaining traction, aligning with the demands of environmentally-conscious consumers. Furthermore, as manufacturers aim for increased efficiency, the integration of advanced technologies like 3D printing and computer-aided design is revolutionizing the bespoke rubber moulding sector. These innovations not only reduce lead times but also enable greater design freedom, resulting in customized solutions that are tailored to the unique challenges faced by different industries. As these trends continue to shape the future of custom rubber solutions, businesses must adapt to leverage these advancements for competitive advantage.

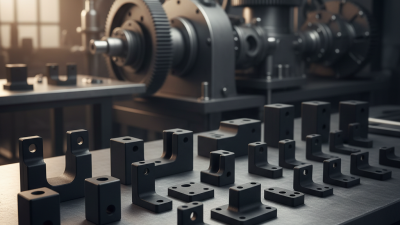

The landscape of custom manufacturing is witnessing a profound transformation driven by bespoke rubber moulding techniques across various key industries. In automotive manufacturing, for instance, the demand for lightweight, durable components has escalated. Bespoke rubber moulding allows manufacturers to create tailored parts that enhance performance while reducing vehicle weight. This precision not only ensures the longevity of components but also contributes to overall fuel efficiency, aligning with industry goals towards sustainability.

In the medical sector, the customization of rubber moulding is vital in producing specialized applications that meet stringent regulatory standards. From seals and grommets to specialized tubing, bespoke techniques enable manufacturers to deliver safe, high-quality components tailored to specific medical devices. This adaptability is crucial as the healthcare industry shifts towards personalized medicine, demanding that production methods evolve in tandem to meet unique patient needs and operational efficiencies.

Additionally, the consumer electronics industry is embracing bespoke rubber moulding for protective casings and seals. With rapid advancements in technology, it is essential for manufacturers to produce components that not only protect products but also enhance user experience. Custom moulding techniques facilitate the development of innovative designs that cater to aesthetic preferences while ensuring functionality, ultimately supporting brands in staying competitive in a fast-paced market.

This chart illustrates the anticipated growth across key industries adopting bespoke rubber moulding techniques by 2025. The data highlights the increasing demand for customization and innovative solutions in various sectors.