Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

In today's competitive manufacturing landscape, the demand for tailored solutions has never been greater. Bespoke Rubber Moulding stands out as a key player in delivering customized products that meet specific requirements across various industries. According to industry expert Dr. Edward Harper, "Bespoke Rubber Moulding not only enhances product functionality but also allows for unparalleled creativity in design." This statement underscores the unique advantages of opting for bespoke solutions in the manufacturing process.

Custom manufacturing through Bespoke Rubber Moulding provides businesses with the flexibility to create components that perfectly fit their needs, ensuring improved performance and efficiency. By utilizing advanced techniques and materials, companies can produce high-quality rubber parts that withstand the rigors of their intended applications. Furthermore, the ability to design and manufacture bespoke products fosters innovation, allowing businesses to develop solutions that create a competitive edge in their market.

As industries evolve and customer expectations become increasingly sophisticated, embracing Bespoke Rubber Moulding becomes a strategic choice for manufacturers looking to thrive. With the potential for customization and the promise of superior quality, the bespoke approach not only meets current demands but also anticipates future challenges, paving the way for successful, sustainable growth.

Bespoke rubber moulding offers a unique approach to custom manufacturing by providing tailored solutions that meet specific project requirements. One of the primary benefits is the precision it affords in producing components that adhere to exact tolerances. This level of customization ensures that each part is compatible with existing systems and functions as intended, reducing the need for adjustments that can disrupt production schedules. Additionally, bespoke moulding allows for the incorporation of unique designs and functionalities that standard parts cannot offer, making it an ideal choice for innovative projects.

Another significant advantage of bespoke rubber moulding is its versatility in material selection. Manufacturers can choose from a wide range of rubber compounds to meet various performance criteria, such as heat resistance, chemical durability, and flexibility. This adaptability enables the production of components for diverse applications, from automotive parts to medical devices. Furthermore, bespoke moulding can lead to improved durability and cost-efficiency. By optimizing materials and manufacturing processes, businesses can achieve higher quality products while effectively managing production costs, ultimately benefiting their bottom line.

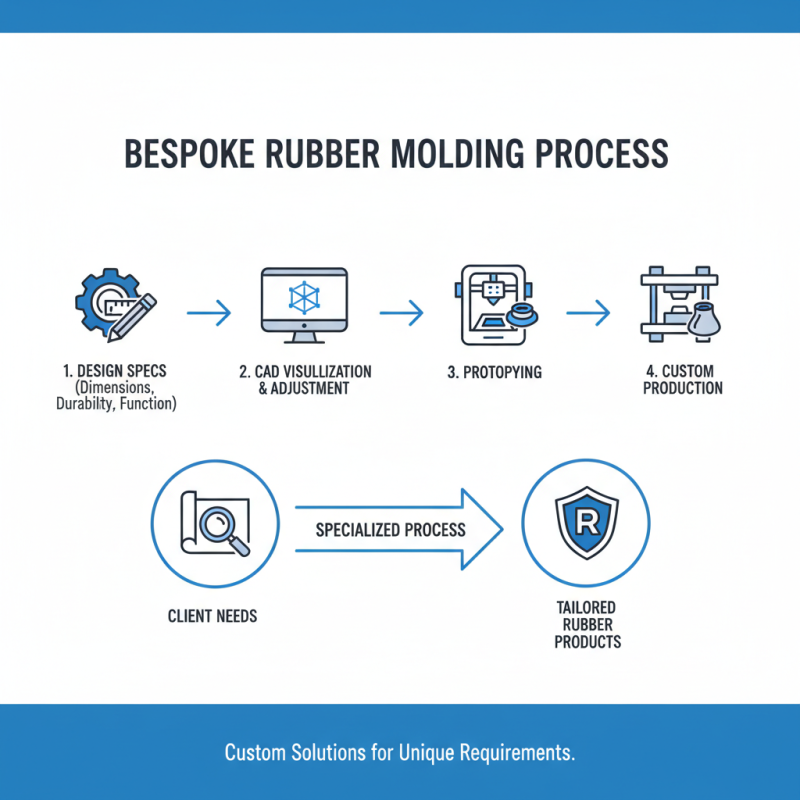

Bespoke rubber moulding is a specialized process that allows manufacturers to create custom rubber products tailored to specific requirements. The process begins with precise design specifications, where the client outlines their needs regarding dimensions, durability, and functional properties. Using advanced CAD (Computer-Aided Design) software, design engineers can visualize the product and make necessary adjustments before moving on to the prototyping phase.

Once the design is finalized, a mould is created, typically from steel or aluminum, to shape the rubber. The selection of rubber compounds is crucial, as different materials provide varying levels of resistance to temperature, chemicals, and wear. In the moulding process, rubber is heated and injected into the mould, where it solidifies into the desired shape. After cooling, the mould is opened, and the finished product is removed. Quality control checks are performed to ensure that each piece meets the specified standards, ensuring reliability and effectiveness for the end use. This meticulous process makes bespoke rubber moulding an ideal choice for industries requiring high precision and customization.

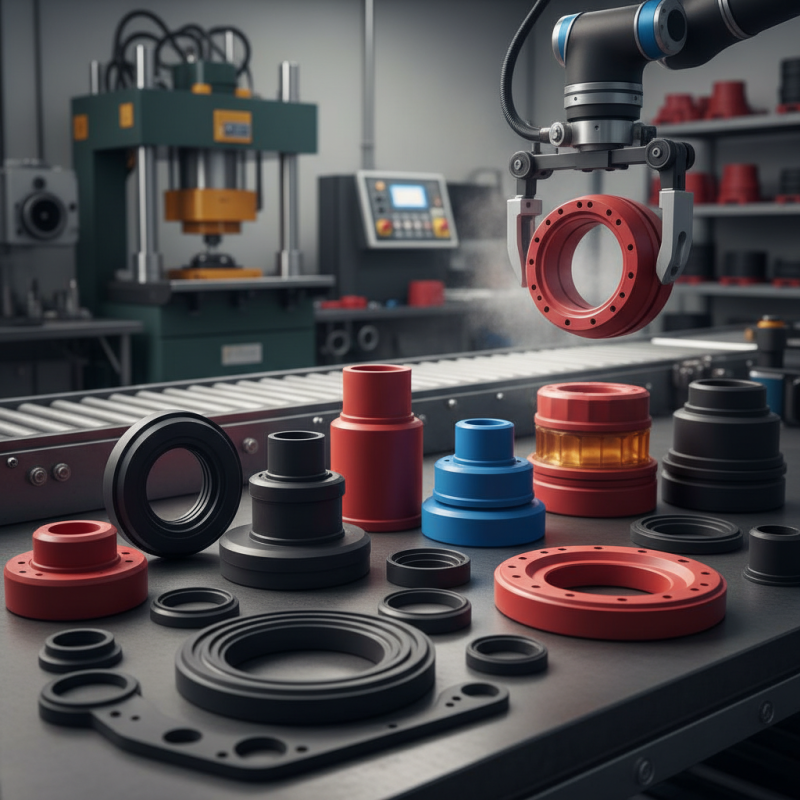

Bespoke rubber moulding offers versatile solutions across various industries, catering to specific manufacturing requirements. In the automotive sector, for example, custom rubber components such as seals, gaskets, and bushings play a critical role in enhancing vehicle performance and durability. These components are designed to withstand extreme temperatures, provide resistance to chemicals, and reduce noise, showcasing the importance of tailored solutions that meet stringent industry standards.

In the medical field, bespoke rubber moulding is essential for producing a wide range of products such as seals for syringes and connectors for medical devices. These components must adhere to high-quality standards for safety and precision, as they are often used in life-saving applications. The ability to customize rubber products ensures that they fit seamlessly into complex medical devices, enhancing functionality while maintaining compliance with regulatory requirements. This adaptability extends to other industries, such as manufacturing electronics and household goods, where custom rubber components improve product reliability and user satisfaction.

When selecting a bespoke rubber moulding provider, several key factors should guide your decision. First and foremost, assess the company's experience and expertise in the industry. A provider with a long-standing reputation and a portfolio of successful projects is likely to have the necessary skills and knowledge to meet your specific manufacturing requirements. Additionally, inquire about the range of rubber materials and types of moulding processes they offer, as flexibility in material selection can significantly impact the performance and cost-effectiveness of your final product.

Another critical factor to consider is the provider’s ability to work collaboratively with you throughout the design and production process. Effective communication and a willingness to adapt to your needs can lead to a more tailored solution. Moreover, examine their quality assurance practices and certifications to ensure they adhere to industry standards. A reliable provider will implement rigorous testing procedures to guarantee that the final products meet your specifications and durability expectations. Ultimately, a thorough evaluation of these aspects will help you choose a bespoke rubber moulding partner that aligns with your unique requirements.

When it comes to manufacturing, the choice between bespoke rubber moulding and mass production methods can significantly impact the quality and suitability of the final product. Bespoke rubber moulding offers the advantage of customization, allowing for tailored solutions that precisely meet the demands of a specific application. Unlike mass production, where standard designs often lead to compromises in quality and functionality, bespoke moulding provides the flexibility to create unique shapes, sizes, and material formulations that are optimized for individual requirements.

In contrast, mass production methods prioritize efficiency and high volume output, which can sometimes sacrifice the intricate details and specific performance characteristics that bespoke options can provide. While mass production may result in lower upfront costs, it can lead to higher long-term expenses if the products do not perform as needed or require modifications later on. Bespoke rubber moulding may have higher initial costs, but it ensures that each item produced aligns closely with the client’s specifications, fostering better performance and longevity in intended applications. This comparison highlights the critical importance of evaluating both methods based on specific project needs, as the choice between custom and standard manufacturing can significantly affect overall product success.

| Criteria | Bespoke Rubber Moulding | Mass Production Methods |

|---|---|---|

| Customization | High level of customization; tailored to specific needs | Limited options; standardized products |

| Production Volume | Ideal for low to mid-volume production | Best suited for high-volume production |

| Lead Time | Longer lead times due to design and setup | Shorter lead times for existing designs |

| Material Selection | Wide range of materials available to meet specific requirements | Limited material options; typically bulk materials |

| Cost | Generally higher cost per unit due to custom work | Lower cost per unit due to economies of scale |

| Quality Control | Rigorous quality assurance tailored to specifications | Standardized quality checks in mass production |