Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

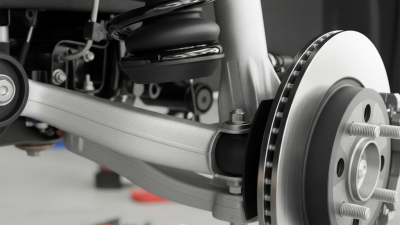

When searching for durable options, Rubber Push Button Covers stand out. These covers serve a vital function, protecting buttons from wear and tear. They are widely used in various industries, including automotive, electronics, and appliances.

Choosing the right Rubber Push Button Cover can be challenging. Factors like material quality, design, and texture affect their durability. Some buyers focus solely on aesthetics, overlooking practical features. This can lead to regret after a product has been purchased.

A wide array of choices exists, but not all are created equal. Buyers must consider factors such as grip and longevity. Even popular models have limitations. Reflecting on these aspects can help consumers make informed decisions, ultimately leading to greater satisfaction with their choice.

Rubber push button covers offer several features that enhance usability and durability. These covers protect buttons from dust and moisture, ensuring they remain functional over time. A good cover can withstand harsh weather conditions. This makes them suitable for outdoor use. The textural surface provides a better grip. Users can easily locate and press the button.

A critical aspect of these covers is their versatility. They come in various sizes and designs to fit different buttons. Some might not have a perfect fit. This can lead to accidental button presses or misalignment. Users should carefully check measurements before purchasing. Soft rubber materials offer comfort and ease of use. However, thinner covers may wear out faster with frequent use.

While most rubber push button covers have many benefits, there are some drawbacks. Over time, exposure to UV light may degrade the material. Colors can fade or become brittle. Not all covers are created equal. Some may be too thick, affecting button sensitivity. Weighing the pros and cons is essential for making an informed choice.

| Features | Benefits | Material Quality | Temperature Resistance (°C) | IP Rating |

|---|---|---|---|---|

| High elasticity | Enhances user comfort and tactile feedback | Injection-molded rubber | -40 to 120 | IP65 |

| High wear resistance | Prolongs product life span | Silicone rubber | -30 to 150 | IP66 |

| UV resistance | Prevents fading and degradation in sunlight | EPDM rubber | -20 to 100 | IP67 |

| Anti-slip surface | Improved grip during operation | Nitrile rubber | -30 to 90 | IP65 |

| Customizable colors | Enhances aesthetic and brand recognition | Natural rubber | -20 to 80 | IP54 |

When looking for rubber push button covers, several types are available in the market. Each type serves different needs and environments. One common type is silicone rubber covers, known for their flexibility and resistance to extreme temperatures. According to industry reports, silicone can withstand temperatures from -60°C to 200°C. This makes it ideal for both indoor and outdoor applications.

Another popular option is thermoplastic elastomer (TPE) covers. These are noted for their durability and ease of customization. Data from the latest market analysis indicates that TPE is gaining traction in consumer electronics. Many manufacturers prefer TPE for its ability to maintain grip even in wet conditions. Shock resistance also plays a crucial role in its popularity. In certain sectors, the demand for TPE covers has seen a growth rate of about 15% annually.

However, it's essential to keep in mind the trade-offs. While silicone and TPE can offer excellent durability, their cost may not always justify their performance in low-demand scenarios. It is helpful to evaluate specific usage environments. Understanding the details of each type can help in making an informed choice.

When selecting rubber push button covers, durability is a key concern. Several factors significantly influence their lifespan. Material quality is paramount. High-grade rubber, such as silicone or thermoplastic elastomers, offers superior resistance to wear and tear. A recent industry report indicates that products made from these materials can last up to 50% longer than those made from standard rubber blends.

Environmental conditions also play a critical role. Exposure to extreme temperatures, UV rays, and moisture can degrade rubber. According to research, covers subjected to high humidity and heat may lose shape and flexibility within months. Regular maintenance can mitigate this, but not all users recognize the importance of care.

Additionally, the button design impacts durability. Rounded edges tend to withstand impacts better than flat designs. A report noted that covers with intricate shapes can trap dirt, which affects performance over time. Users sometimes overlook this, leading to premature failure of the cover. Recognizing these factors is essential for making informed choices in rubber push button covers.

When looking for durable rubber push button covers in 2026, several notable options stand out. These covers are essential for protecting against wear and tear. A good cover should be flexible yet sturdy. A well-made rubber cover can withstand harsh weather conditions and daily use. Look for textures that provide a better grip. Smooth surfaces can slip. The tactile feel matters greatly.

Choosing the right brand can make a difference. Some brands have spent years developing their products. They prioritize robustness and longevity. It's intriguing how some alternatives fail to meet expectations. Inferior materials can lead to quick deterioration. Even popular choices can sometimes disappoint. Feedback from users often offers valuable insights.

Consider the design as well. Aesthetics can't be overlooked even in utility items. Some covers come in various colors and shapes. Fun designs can enhance functionality. However, a flashy design doesn't always mean better performance. Reflecting on these aspects is essential. Durability and style should coexist harmoniously. A careful selection process could ensure satisfaction in the long run.

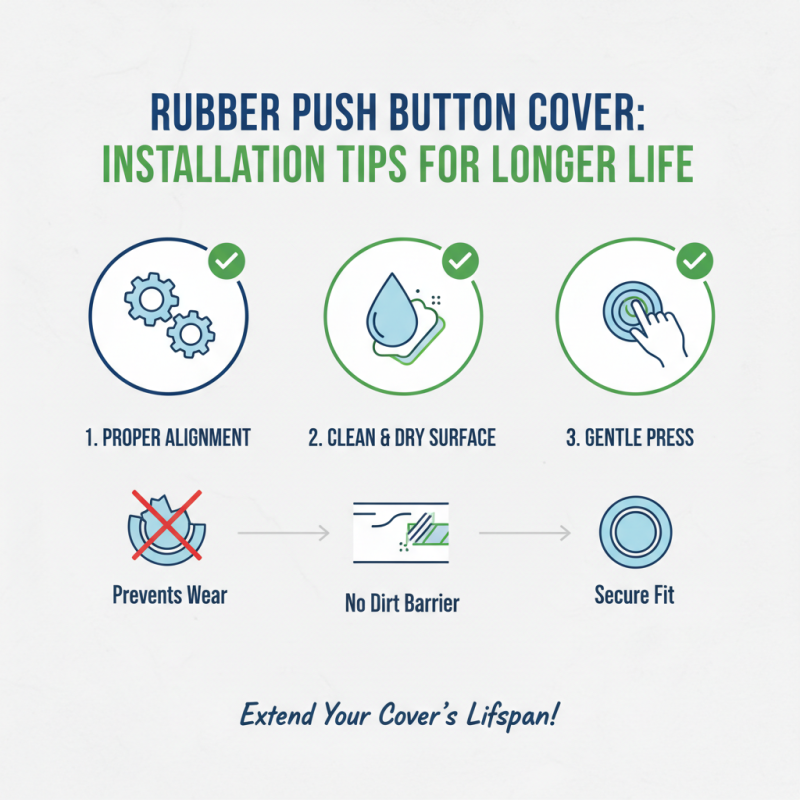

When it comes to rubber push button covers, installation plays a vital role in their lifespan. Proper alignment is crucial. Misaligned covers can wear out faster. Make sure the surface is clean and dry. Any dirt can create a barrier, leading to premature damage. A gentle press during installation can help secure the cover in place.

Maintenance is just as important for durability. Regular checks are essential. Look for signs of wear or tears. Even small cracks can worsen over time. Cleaning the covers with mild soap and water can extend their lifespan. Harsh chemicals should be avoided. They can degrade the rubber material. If you notice any issues, consider replacing them sooner rather than later.

Some users might overlook these steps. It often leads to early replacement. Don't rush the installation process. Take the time to ensure everything is in place. Neglecting maintenance can result in greater costs down the line. Making a habit of these practices can ensure your button covers last longer.