Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

In the ever-evolving landscape of industrial tools and equipment, the choice of Tapered Rubber Plugs has become increasingly critical for professionals across various sectors. As reported in the latest industry analysis by the Global Rubber Plug Market Research Report, the demand for Tapered Rubber Plugs is expected to grow steadily, with an estimated market value projected to reach $150 million by 2025. This rise is driven by their versatility and effectiveness in providing leak-proof seals for diverse applications, from plumbing to automotive maintenance.

According to industry expert Dr. Anna Wells, a leading researcher in elastomer materials, “Choosing the right Tapered Rubber Plug can significantly enhance operational efficiency and prevent costly leaks.” Her insights highlight the importance of understanding the specific requirements of your project, including considerations such as size, material properties, and application context. With numerous options available in the market, it can be daunting to select the optimal Tapered Rubber Plug for your unique needs. Therefore, this article aims to guide you through the top ten selections in 2025, ensuring that you make an informed decision that aligns with your operational demands.

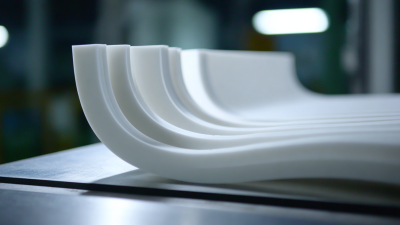

When selecting tapered rubber plugs in 2025, it's essential to understand the various types available and their specific applications. Generally, these plugs can be categorized into standard, reinforced, and custom-designed options. Standard tapered rubber plugs are often used in everyday applications, while reinforced plugs are designed for high-pressure situations, often found in industrial settings.

According to a recent market analysis report by Grand View Research, the global market for rubber plugs is expected to reach approximately $400 million by 2025, indicating a growing demand for more specialized products.

The customization of tapered rubber plugs is becoming increasingly important, particularly for industries that require unique dimensions and material properties. A survey conducted by Technavio found that 42% of manufacturers prefer custom solutions to cater to their specific needs, emphasizing the trend towards tailored products.

Additionally, advanced manufacturing technologies such as 3D printing are making it easier to create plugs that meet exact specifications, thus expanding the scope of available options. Understanding these distinctions can help consumers make informed choices based on their specific requirements.

When selecting tapered rubber plugs for specific applications, several key factors come into play. First, the size and shape of the plug must match the bore of the item it will seal. Tapered plugs are designed to fit snugly into various openings, so it’s essential to measure the diameter accurately at both the narrow and wider ends. This ensures a secure fit and optimal sealing efficiency, preventing leaks and contamination.

Material composition is another critical factor to consider. Tapered rubber plugs can be made from different types of rubber, such as silicone, neoprene, or EPDM, each offering unique properties like temperature resistance, chemical compatibility, and durability. For instance, if the application involves exposure to extreme temperatures or harsh chemicals, selecting a plug made from a resistant material will extend its lifespan and effectiveness. Understanding the specific operating environment will guide users in making the right material choice for their needs.

When it comes to choosing tapered rubber plugs, the quality of the material plays a critical role in determining both performance and durability. High-quality rubber materials are designed to withstand a range of temperatures and environmental conditions without degrading. This is essential for preventing leaks and ensuring a secure fit. Additionally, superior materials can resist wear and tear better, leading to extended service life and reduced need for replacements.

Tip: Always look for tapered rubber plugs made from premium-grade rubber compounds. These materials not only provide excellent sealing capabilities but also enhance resistance to chemicals and UV exposure, which is crucial for applications in harsh environments.

Furthermore, consider the hardness of the rubber. Softer materials may offer better compression and conform to surface irregularities, while harder rubber plugs might offer more stability and durability under extreme conditions. Understanding the specific needs of your application can guide you in selecting the right hardness.

Tip: Perform a side-by-side comparison of various rubber plugs, focusing on their material specifications and performance ratings to ensure you are getting the best quality for your needs.

When selecting tapered rubber plugs, evaluating cost-effectiveness is crucial in ensuring a balance between price and quality. Tapered rubber plugs come in various price ranges, influenced by factors such as material, size, and brand. It is essential to consider not only the upfront cost but also the longevity and performance of the product. A lower-priced option may initially seem enticing; however, if it wears out quickly or fails to provide an adequate seal, the long-term costs could outweigh the initial savings.

Quality often reflects the reliability of a tapered rubber plug in various applications, from home repairs to industrial uses. Investing in higher-quality plugs can result in better performance and fewer replacements over time. To evaluate cost-effectiveness, consumers should look for reviews, product ratings, and warranty offerings. This ensures that even if the purchase price is higher, the return on investment through enhanced durability and effectiveness can lead to significant savings in the long run.

Balancing these aspects will lead to a more informed decision that satisfies both budgetary constraints and functional requirements.

When selecting tapered rubber plugs, it's essential to consider top brands that have established a reputation for quality and reliability. In 2025, several manufacturers stand out in this niche. Brands like Oatey and DuraSeal have been recognized for their durable materials and effective sealing capabilities. Oatey, in particular, offers a wide range of sizes and options, making it easy for consumers to find a plug that fits their specific needs, whether it's for plumbing, automotive, or industrial applications.

Another noteworthy brand is Raven Products, known for its innovative designs that provide enhanced functionality and ease of use. Their tapered rubber plugs come in various durometers, ensuring that users can select the right level of firmness for their application. Additionally, Raven's commitment to sustainability, using eco-friendly materials, resonates well with environmentally conscious consumers. As you evaluate your choices in tapered rubber plugs, focusing on these reliable brands will help ensure you make informed decisions that meet your requirements effectively in 2025.

| Feature | Description | Size Range | Material | Durability | Average Price |

|---|---|---|---|---|---|

| Water Resistance | Excellent for usage in wet environments. | Small to Large (1" to 6") | Silicone Rubber | 5 Years | $3 - $10 |

| Temperature Resistance | Stable performance in extreme temperatures. | Medium (2" to 4") | Neoprene | 3 Years | $5 - $12 |

| Chemical Resistance | Resistant to various chemicals, suitable for industrial use. | All Sizes | EPDM Rubber | 4 Years | $4 - $15 |

| Flexibility | Maintains flexibility under varying conditions. | Small (1" to 3") | Natural Rubber | 3 Years | $2 - $8 |

| Eco-friendliness | Made from sustainable sources, biodegradable. | Variety of sizes | Biodegradable Rubber | 2 Years | $6 - $14 |