Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

In the diverse world of engineering and manufacturing, Bracket Rubber plays a crucial role in providing stability and support in various applications. As an expert in the field, Dr. Emily Carter, a materials engineer with over a decade of experience, emphasizes, "Bracket Rubber is essential for ensuring that components remain securely in place, while also offering the necessary cushioning to absorb shocks and vibrations." This versatility makes Bracket Rubber a preferred choice across multiple industries, from automotive to construction.

Understanding the functionality and application of Bracket Rubber is vital for optimal performance in any project. It not only contributes to the longevity of equipment but also enhances user safety by minimizing the risk of damage caused by movement or impact. As industries increasingly seek materials that combine durability with flexibility, the importance of high-quality Bracket Rubber becomes ever more pronounced. In this article, we will delve into the various uses of Bracket Rubber and explore how its unique properties make it a staple in modern manufacturing processes.

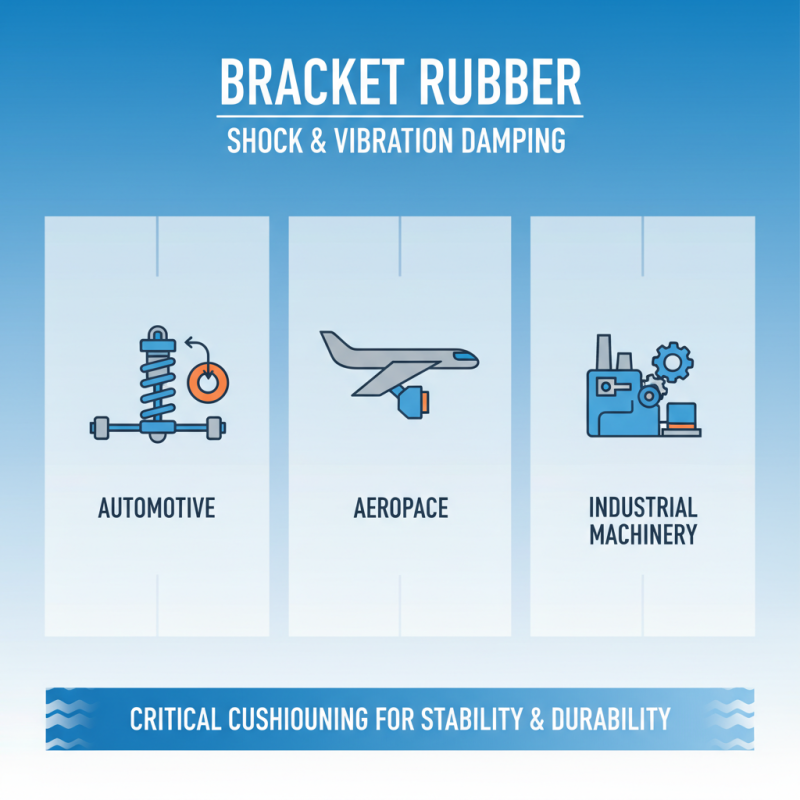

Bracket rubber, often utilized in various mechanical applications, serves a critical function as a cushioning or damping element. Its primary purpose is to absorb shock and vibration, ensuring that assemblies remain stable and operate smoothly. Typically made from durable materials like elastomers, bracket rubber is designed to withstand various environmental factors, making it suitable for both indoor and outdoor use. It is commonly found in automotive, aerospace, and industrial machinery, where vibrations from engines, pumps, or heavy machinery can lead to wear and tear over time.

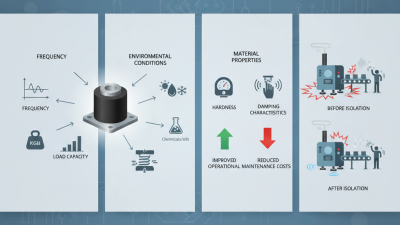

When selecting bracket rubber for a specific application, it's essential to consider factors such as the load it will bear, the frequency of vibrations, and the temperature variations it will encounter. Proper installation is also crucial; ensuring that the rubber is placed correctly within the bracket can significantly enhance performance and longevity.

Tips: Always check the durometer hardness of the rubber to match the requirements of your application. The right hardness ensures optimal absorption of vibrations and impacts. Additionally, regular maintenance checks can help identify any wear on the bracket rubber, allowing for timely replacements and minimizing operational downtime.

Bracket rubber is a specialized material known for its unique composition and versatile properties, making it a popular choice across various industries. Typically made from synthetic rubber compounds, bracket rubber exhibits excellent elasticity, durability, and resistance to weathering and chemicals. These characteristics allow it to maintain its performance consistently, even under fluctuating temperatures and harsh environmental conditions.

One of the standout features of bracket rubber is its ability to absorb shock and vibration, making it ideal for applications in automotive and industrial machinery. Its flexible nature enables it to fit snugly into brackets and mounts, providing stability and support. Additionally, bracket rubber's high tensile strength ensures that it can withstand significant stress without deforming or losing its structural integrity.

Tips: When selecting bracket rubber for your project, consider the specific environmental conditions and potential exposure to chemicals. Testing the material under actual use conditions can help ensure that it meets performance expectations. Always consult with manufacturers for guidance on the appropriate type of bracket rubber best suited for your application to achieve optimal results.

Bracket rubber is an essential component across various industries, serving multiple functions that enhance the performance and reliability of different applications. In the automotive sector, bracket rubber is primarily used for vibration damping and noise reduction. The global automotive rubber market is projected to reach approximately $50 billion by 2025, highlighting the integral role of components like bracket rubber in enhancing vehicle comfort and longevity. By isolating vibrations from the engine and road, bracket rubber helps maintain structural integrity and noise levels within acceptable limits, improving the overall driving experience.

In the construction industry, bracket rubber plays a crucial role in supporting heavy structural elements while also accommodating movement caused by thermal expansion or seismic activity. According to a report by Research and Markets, the global market for construction rubber products is expected to grow at a CAGR of 3.5% through 2024. The elasticity and durability of bracket rubber allow it to effectively absorb shocks and distribute loads evenly, which is vital in ensuring the stability of buildings and infrastructure. Furthermore, its resistance to weathering and chemical exposure makes it suitable for outdoor and industrial applications, where environmental conditions can be harsh and unpredictable.

In the electronics sector, bracket rubber is utilized for cushioning and protecting sensitive equipment from impact and vibration. The growing trend towards miniaturization in electronics has increased the demand for innovative packaging solutions that incorporate bracket rubber to safeguard components. Reports suggest that the global electronics packaging market is anticipated to reach $30 billion by 2026, driven by advancements in technology and the need for durable, lightweight materials. By providing a protective barrier, bracket rubber not only extends the lifespan of electronic devices but also enhances their performance, making it a critical component in the ever-evolving tech landscape.

Bracket rubber, commonly known for its flexibility and durability, plays a vital role in various applications found in our daily lives. One significant use is in automotive settings, where bracket rubber serves as a cushioning component to minimize vibrations and impacts, thereby enhancing the comfort of the ride. Additionally, it is widely employed in household appliances, providing insulation and ensuring that devices operate smoothly and quietly.

In construction, bracket rubber is integral to mounting systems for pipes and electrical conduits, offering support while allowing for necessary movement due to temperature changes. This versatility makes bracket rubber a staple in DIY projects as well, where it can be used to secure items in place without compromising their integrity.

Tips: When using bracket rubber in any application, ensure that the material selected is suited for the specific environment—such as heat resistance for high-temperature areas or water resistance for damp environments. Additionally, always check for wear and tear, as maintaining the integrity of bracket rubber components is crucial for long-term performance and safety.

Bracket rubber, an essential component in various manufacturing and construction processes, offers numerous advantages that enhance efficiency and longevity. One of the primary benefits of using bracket rubber is its ability to absorb shock and vibrations. In construction environments, this property helps in maintaining structural integrity by reducing the strain on materials and joints, thereby prolonging the lifespan of the structures involved. The flexibility of bracket rubber allows it to conform to irregular surfaces, ensuring a tight fit that minimizes gaps and potential points of failure.

Additionally, bracket rubber is resistant to a wide range of environmental factors, including moisture and temperature fluctuations. This durability is particularly beneficial in manufacturing settings where equipment may be subjected to harsh conditions. Its chemical resistance also makes it suitable for industries that deal with corrosive substances, providing a reliable solution that safeguards machinery and components from wear and tear.

By integrating bracket rubber into their operations, manufacturers and construction professionals can not only improve the safety and performance of their projects but also reduce maintenance costs over time.