Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Bracket rubber is an essential component used across various industries, providing a vital role in securing and insulating different parts in machinery and equipment. The global rubber market is poised for significant growth, with a report from Research and Markets estimating a compound annual growth rate (CAGR) of 5.3% from 2021 to 2026. This growth highlights not only the increasing demand for rubber materials but also the importance of selecting the right type for specific applications.

Choosing the appropriate bracket rubber is crucial, as it affects both the performance and durability of the equipment. With diverse options available, including EPDM, neoprene, and natural rubber, each type offers unique properties that cater to specific environmental conditions and mechanical requirements. According to a recent study by MarketsandMarkets, the increasing focus on infrastructure development and machinery maintenance is driving the demand for high-quality rubber components, reinforcing the need for informed selection processes.

In this article, we will delve deeper into what bracket rubber is, its various characteristics, and the critical factors to consider when selecting the right one to meet your unique requirements. Understanding these aspects will ensure optimal performance and longevity in your applications, aligning with industry standards and expectations for quality.

Bracket rubber is an essential component in various industries, serving multiple purposes in different applications. Primarily, it acts as a cushioning material that absorbs vibrations and shocks, providing stability and protection to mounted equipment. This is particularly important in automotive, construction, and manufacturing sectors where machinery is subject to continuous movement and potential impact. By dampening vibrations, bracket rubber helps extend the lifespan of sensitive components and reduces wear and tear, ensuring smoother operation in environments where mechanical stress is common.

In addition to vibration damping, bracket rubber also plays a crucial role in sealing and insulation. It can be used to create airtight seals around brackets, which is vital in preventing dust, moisture, and other contaminants from entering sensitive machinery. This functionality is especially critical in industries like HVAC, marine, and electronics, where maintaining clean and controlled environments is paramount. When selecting the right bracket rubber, it is essential to consider factors such as material composition, hardness, and temperature resistance to ensure optimal performance for the specific application. The right choice can significantly enhance both durability and efficiency, making it a vital factor in the design and operation of various mechanical systems.

This bar chart illustrates the usage frequency of bracket rubber in various applications. Each bar represents a different application where bracket rubber is utilized, showcasing the varying levels of frequency of use.

When selecting bracket rubber for your project, understanding the different types available is essential to ensure optimal performance and durability. The most common materials used for bracket rubber include natural rubber, neoprene, and EPDM (ethylene propylene diene monomer). Natural rubber provides excellent elasticity and tensile strength, making it suitable for applications that involve dynamic loads. However, it has limited resistance to environmental factors like UV light and ozone, which can lead to degradation over time.

Neoprene, on the other hand, excels in applications where chemical resistance is a priority. It can withstand oil, solvents, and temperature fluctuations, making it ideal for use in automotive and industrial settings. Additionally, neoprene offers good weather resistance, which contributes to its longevity in outdoor applications. EPDM is another excellent choice, particularly for outdoor environments, as it provides superior resistance to UV rays, ozone, and extreme temperatures. It is frequently used in roofing and waterproofing applications due to its exceptional durability.

Ultimately, the choice of bracket rubber material should be guided by the specific requirements of your project, such as environmental conditions, exposure to chemicals, and mechanical stresses. Evaluating these factors will help you choose the right type of rubber that not only meets functional needs but also ensures the longevity and effectiveness of your installation.

| Type of Bracket Rubber | Material | Temperature Resistance (°C) | Chemical Resistance | Common Applications |

|---|---|---|---|---|

| Natural Rubber | Natural Latex | -50 to 90 | Poor to Moderate | General Industrial |

| EPDM Rubber | Ethylene Propylene Diene Monomer | -50 to 120 | Excellent | Automotive Seals, Roofing |

| Neoprene Rubber | Chloroprene | -40 to 120 | Good | Electrical Insulation, Marine Applications |

| Silicone Rubber | Silicon-based | -60 to 200 | Excellent | Medical Devices, Food Processing |

| Viton Rubber | Fluoroelastomer | -20 to 200 | Excellent | Aerospace, Chemical Processing |

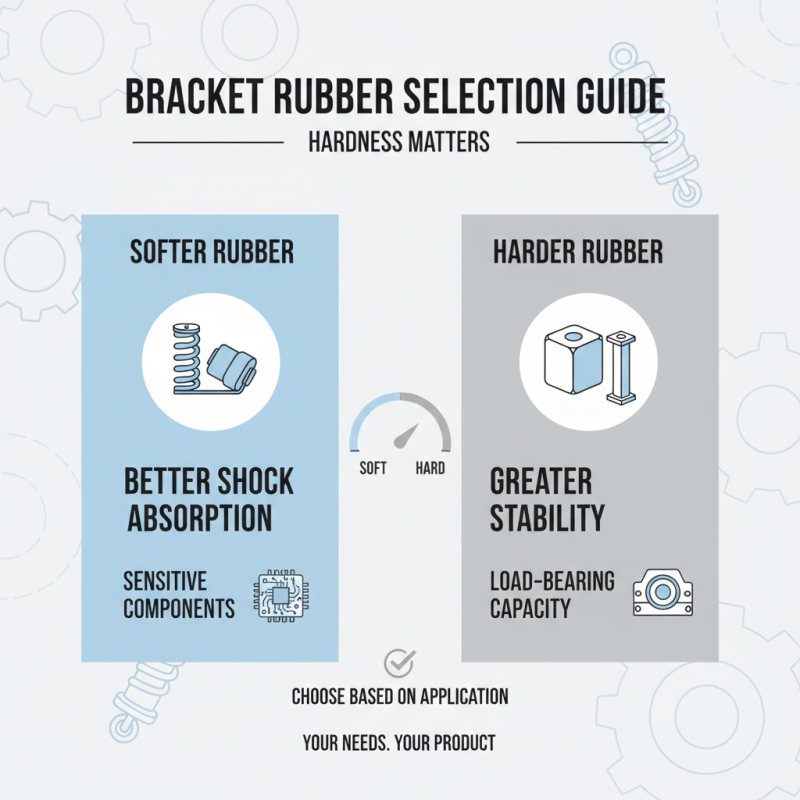

When selecting bracket rubber, several key factors should guide your decision to ensure that you get the right product for your needs. One essential aspect is the hardness of the rubber. Different applications will require varying levels of softness or hardness. Softer rubbers typically provide better shock absorption, making them ideal for sensitive components, while harder rubbers offer greater stability and load-bearing capacity.

Another important consideration is the environment in which the bracket rubber will be used. Factors such as temperature, humidity, and exposure to chemicals can significantly affect the performance and longevity of rubber. For instance, if the rubber will be placed in a high-temperature area, you should choose a material that can withstand heat without degrading.

Tips: Always check the specifications and performance characteristics of the bracket rubber. Evaluate its temperature tolerance and chemical resistance before making a purchase. Additionally, consulting with industry experts can provide insights into the best materials for your specific application, ensuring optimal performance and durability.

When purchasing bracket rubber, avoiding common pitfalls can significantly impact its performance and longevity. One frequent mistake buyers make is overlooking the material specifications. High-quality bracket rubber is often made from compounds that provide durability and resistance to environmental factors, such as temperature fluctuations and UV exposure. According to industry studies, selecting the correct material can enhance the product lifespan by up to 30%, making it essential to understand the requirements specific to your application.

Another common error is neglecting to consider the size and fit of the rubber. Many users mistakenly assume that a standard size will work for all brackets. However, according to a recent market analysis, improper sizing is responsible for approximately 25% of bracket rubber failures. Taking precise measurements and ensuring compatibility with your specific setup is crucial before making a purchase.

Tips for selecting the right bracket rubber include checking technical datasheets for detailed information about the material properties and performance metrics. Additionally, consulting with experts or suppliers can provide insights tailored to your unique application needs. Lastly, always ask about warranty and support options to safeguard against premature wear or performance issues.

Maintaining the longevity of bracket rubber is essential for ensuring optimal performance in various applications. Regular inspection and cleaning are critical practices that can prevent premature wear and tear. Over time, dust and debris can accumulate, causing friction and reducing the rubber's effectiveness. A gentle wipe with a damp cloth can remove surface contaminants, while periodic thorough cleaning with a mild detergent will help maintain its integrity and elasticity.

Another vital aspect of maintenance is the proper storage of bracket rubber. Keeping it in a cool, dry place away from direct sunlight can significantly extend its lifespan. High temperatures and UV exposure can lead to degradation, making the rubber brittle and prone to cracking. Additionally, avoid stretching or compressing the rubber when not in use, as this can alter its shape and diminish its resilience over time.

Lastly, it's important to periodically check for signs of wear, such as cracks or deformities, and replace the rubber if necessary. Implementing a routine check-up can help identify potential issues early, ensuring that your bracket rubber performs effectively throughout its service life. Taking these steps will not only enhance performance but also save on future replacement costs.