Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

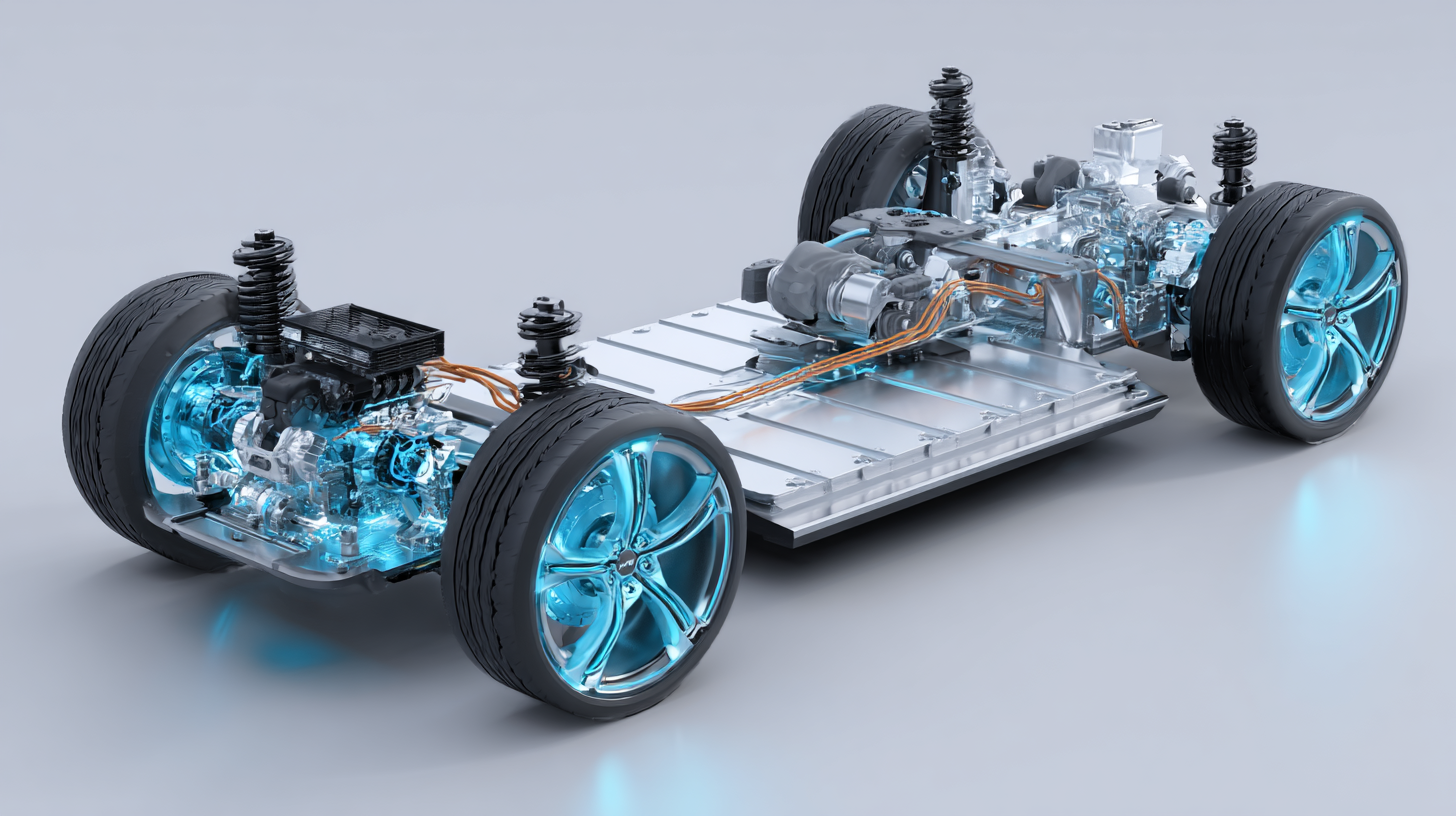

The automotive industry is undergoing a significant transformation as manufacturers increasingly prioritize safety and performance in their designs. One critical component that plays a pivotal role in achieving these objectives is Bracket Rubber. According to a recent report by MarketsandMarkets, the global automotive rubber market is projected to reach USD 42.43 billion by 2025, growing at a CAGR of 5.7%. This surge is largely attributed to the rising demand for advanced materials that enhance vehicle durability, vibration dampening, and ride comfort.

Bracket Rubber serves a vital function in various assemblies, providing not only structural support but also contributing to the overall safety of the vehicle by absorbing shocks and minimizing noise. As automotive engineers strive to meet rigorous safety standards and improve vehicle dynamics, understanding the multifaceted role of Bracket Rubber becomes increasingly essential in modern automotive design and safety engineering.

In modern automotive design, the significance of bracket rubber cannot be overstated, particularly in the context of noise and vibration control. According to a report by the Automotive Research Association, vehicle noise can contribute to driver fatigue and discomfort, with up to 80% of occupants reporting dissatisfaction with cabin noise levels. Bracket rubber components play a crucial role in mitigating these issues by acting as isolators that dampen vibrations transferring from the engine and suspension to the cabin. This not only enhances the overall driving experience but also aligns with stringent noise regulations set forth by authorities such as the Federal Motor Vehicle Safety Standards.

Moreover, the integration of high-performance bracket rubber into vehicles has been shown to reduce vibration-related wear and tear. A study published by the International Journal of Automotive Engineering revealed that incorporating advanced rubber formulations can decrease vibration transmission by up to 30%. This reduction not only contributes to increased passenger comfort but also improves the longevity of critical vehicle components. As automotive manufacturers continue to focus on delivering quieter and more refined vehicles, the relevance of bracket rubber in achieving these goals is more critical than ever, proving itself as an essential element in the intersection of design, safety, and user satisfaction.

Bracket rubber plays a crucial role in enhancing vehicle structural integrity, acting as a vibration dampener and providing essential support for various automotive components. According to a report by the International Journal of Automotive Engineering, the proper selection and design of bracket rubber can reduce vibrations by up to 30%, subsequently increasing the longevity of critical parts such as suspension systems and engine mounts. This reduction in vibrations not only improves overall vehicle comfort but also minimizes wear and tear, ensuring better performance over time.

Bracket rubber plays a crucial role in enhancing vehicle structural integrity, acting as a vibration dampener and providing essential support for various automotive components. According to a report by the International Journal of Automotive Engineering, the proper selection and design of bracket rubber can reduce vibrations by up to 30%, subsequently increasing the longevity of critical parts such as suspension systems and engine mounts. This reduction in vibrations not only improves overall vehicle comfort but also minimizes wear and tear, ensuring better performance over time.

Moreover, the integration of advanced materials in bracket rubber design has shown promising results in safety engineering. A study published by the Society of Automotive Engineers (SAE) found that modern bracket rubber can improve crashworthiness by absorbing impact forces more effectively, potentially decreasing injury risk by 20% during collisions. As vehicles continue to evolve, the significance of bracket rubber in maintaining structural integrity and enhancing safety features cannot be overstated, making it an essential focus area for automotive engineers and safety experts alike.

Bracket rubber plays a crucial role in modern automotive design, specifically in enhancing the safety performance of vehicles. These elastomeric materials are strategically used in various automotive components, including suspension systems and exterior parts, to absorb vibrations and impacts. When a vehicle experiences a collision, the bracket rubber effectively dampens the forces transmitted to the car's structure and occupants, thereby reducing the likelihood of injury. By ensuring that components remain securely in place during high-stress events, bracket rubber contributes to the overall integrity and resilience of the vehicle.

Moreover, the safety enhancements provided by bracket rubber materials extend beyond mere impact absorption. Modern bracket rubber formulations can be engineered to withstand extreme temperatures and environmental conditions, ensuring their reliability over the lifespan of a vehicle. This durability helps maintain optimal performance during dynamic driving conditions, thereby supporting the vehicle's stability and control. As automotive design continues to prioritize safety, the ongoing development and integration of advanced bracket rubber materials will play an essential role in creating vehicles that not only meet stringent safety standards but also protect passengers effectively in various scenarios.

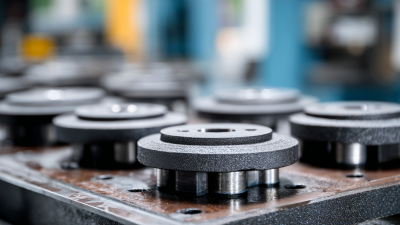

Bracket rubber plays a critical role in modern automotive design, serving various applications that enhance safety, comfort, and performance. Primarily used as a mounting component, bracket rubber cushions vibrations and impacts between the vehicle's chassis and its components. This flexibility not only helps to maintain structural integrity but also reduces noise, contributing to a more pleasant driving experience. Different types of bracket rubber, such as natural rubber, synthetic rubber, and polyurethane, are tailored to meet specific performance requirements, such as temperature resistance and durability.

In automotive applications, bracket rubber is utilized in places like engine mounts, suspension systems, and body mounts. Engine mounts, for instance, rely on high-quality rubber to absorb engine vibrations, ensuring a smooth ride while protecting the vehicle's structure from stress and wear. Similarly, in suspension systems, bracket rubber is essential for stabilizing shocks and struts, allowing for better handling and comfort on the road. As automotive design continually evolves, the selection of appropriate bracket rubber types becomes integral to achieving safety standards and enhancing overall vehicle performance.

The future of automotive design increasingly hinges on innovations in materials, particularly in the realm of bracket rubber technology. This sector is not only experiencing significant growth, projected to climb from $88.97 billion in 2025 to over $108.32 billion by 2034, but is also moving towards sustainable engineering solutions. The demand for high-performance and eco-friendly materials is shaping the landscape of automotive manufacturing, fostering a new era where bracket rubber can offer enhanced durability while minimizing environmental impacts.

As companies invest in technological advancements, the integration of sustainable practices in the production of bracket rubber is becoming essential. This shift is influenced by global trends that emphasize reducing carbon footprints and enhancing recyclability. The automotive market's commitment to innovation reflects a broader movement towards green technologies, where bracket rubber can serve as a key component in ensuring safety and performance without compromising ecological integrity. Through such developments, the automotive industry can achieve a harmonious balance between safety engineering and environmental responsibility, paving the way for a more sustainable future.