Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

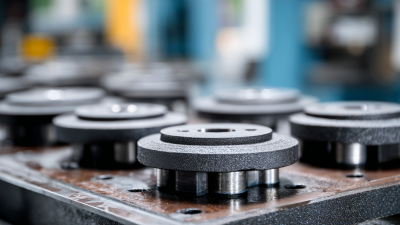

When embarking on a project that requires durable and versatile materials, selecting the right Molded Rubber Components is crucial for achieving optimal performance and longevity. The vast array of rubber products available on the market can make this choice daunting, as each component is tailored for specific applications and conditions. Understanding the fundamental characteristics and advantages of various molded rubber options, such as their resilience to environmental factors and their capacity to withstand mechanical stress, can greatly influence the success of your project. This guide aims to equip you with the necessary knowledge to navigate the decision-making process effectively, ensuring that you select Molded Rubber Components that not only meet your technical specifications but also align with your project goals and budget constraints. By considering critical factors such as material properties, manufacturing processes, and application-specific requirements, you can make an informed choice that enhances the overall quality and reliability of your final product.

When selecting molded rubber components for your project, it's essential to understand the various types of molded rubber compounds available and their unique properties. The global molded rubber market is projected to reach approximately $20 billion by 2026, growing at a compound annual growth rate (CAGR) of around 4.5% according to a recent report by MarketsandMarkets. This growth is driven by the increasing demand for rubber components in automotive, aerospace, and industrial sectors, where performance and durability are critical.

Different types of molded rubber compounds cater to specific application needs. For instance, EPDM (Ethylene Propylene Diene Monomer) rubber is known for its excellent weather and ozone resistance, making it suitable for outdoor applications. On the other hand, silicone rubber offers outstanding thermal stability and is often utilized in high-temperature applications.

According to a study by Grand View Research, the increasing focus on lightweight materials in automotive applications has further fueled the demand for specialty molded rubber compounds, such as nitrile rubber and fluorosilicone, which provide enhanced oil and grease resistance. Understanding these distinctions is crucial for selecting the most efficient materials that align with your project requirements.

When selecting molded rubber components for your project, understanding key performance metrics is essential. Three critical factors to consider are hardness, compression set, and temperature resistance.

Hardness, measured on the Shore scale, determines how soft or hard the rubber will feel and how well it can withstand deformation under pressure. Selecting the right hardness can enhance the longevity and functionality of your components.

Hardness, measured on the Shore scale, determines how soft or hard the rubber will feel and how well it can withstand deformation under pressure. Selecting the right hardness can enhance the longevity and functionality of your components.

Compression set is another vital metric; it refers to the material's ability to return to its original shape after being compressed. A lower compression set indicates better performance in applications where the rubber is frequently under load. It’s crucial to choose materials with a suitable compression set to ensure reliability and durability in high-stress environments.

Tips: Always check the manufacturer’s specifications for compression set ratings, as they can vary significantly between different rubber compounds. Consider your project’s temperature fluctuations when evaluating temperature resistance; materials with higher resistance will maintain their properties better under extreme conditions. Finally, consult with suppliers to ensure that the hardness meets the specific mechanical requirements of your application, as this will directly impact the performance of the molded components.

When selecting molded rubber components for projects, it is crucial to assess environmental factors such as chemical resistance and UV stability. UV exposure can significantly impact rubber materials, leading to deterioration that affects mechanical properties and longevity. A study indicates that UV degradation can cause both physical and chemical breakdown, which in turn can result in the release of harmful substances and microplastics into the environment. This degradation raises concerns not just for the longevity of molded rubber components but also for their interaction with potential pathogens and pollutants.

Understanding the nuances of UV stability allows manufacturers to better formulate rubber compounds that can withstand prolonged exposure to sunlight and environmental factors. Certain additives and treatments can enhance the UV resistance of rubber components, minimizing degradation and maintaining their integrity over time. As we advance photocatalytic strategies for managing plastic waste, a similar approach could be beneficial for developing more resilient rubber materials, ensuring they remain effective and safe throughout their intended lifespan in various applications, particularly those exposed to harsh environmental conditions.

| Material Type | Chemical Resistance | UV Stability | Temperature Range (°C) | Applications |

|---|---|---|---|---|

| EPDM | Excellent: water, alcohols, and some acids | Very Good | -50 to 120 | Automotive, roofing, seals |

| Nitrile (Buna-N) | Good: oils, fuels, and some solvents | Moderate | -40 to 100 | Oil seals, gaskets, hoses |

| Silicone | Good: water and some chemicals | Excellent | -60 to 200 | Medical, food industry, seals |

| Neoprene | Good: oils, acids, and some solvents | Good | -40 to 120 | Wet applications, automotive parts |

| Fluoroelastomer | Excellent: fuels, chemicals, and extreme environments | Excellent | -20 to 200 | Aerospace, automotive, chemical processing |

When embarking on mobile app development in 2025, understanding the cost factors is essential for balancing quality with budget constraints. Key elements influencing costs include the complexity of the app, desired features, and the development team's expertise. In this rapidly evolving landscape, features such as AI integration or enhanced security protocols can significantly increase both development time and expenses. Therefore, it is crucial to set clear project goals and prioritize features to avoid unnecessary spending.

Tips: One effective budgeting strategy is to conduct a detailed market analysis. This analysis helps to outline expected costs and potential returns, enabling more informed decisions on which features to include. Additionally, consider phased development, which allows for iterative improvements based on user feedback while spreading costs over time. Lastly, leveraging cloud computing can offer flexibility in managing resources, thus optimizing your overall budget. By carefully evaluating these cost-related factors and implementing strategic budgeting, you can ensure the project's viability while maintaining high-quality standards.

When selecting molded rubber components for industrial applications, compliance with industry regulations and standards is of utmost importance. These standards often dictate the material properties, safety requirements, and performance specifications essential for various applications. Manufacturers must ensure that their molded rubber products are compliant with regulations set forth by organizations such as the FDA for food-grade materials or ASTM International for general safety and performance criteria. Adhering to these guidelines not only enhances product reliability but also significantly reduces liability risks.

Moreover, the type of industry dictates specific requirements as well. For instance, automotive components must withstand extreme temperatures and conditions while adhering to standards such as ISO and SAE. In the medical field, molded rubber components must pass rigorous testing to ensure biocompatibility and safety for patient use. Therefore, understanding the applicable compliance and standards is crucial in the initial stages of product selection, enabling project managers to choose materials that not only meet their project needs but also align with legal and safety requirements. This proactive approach ultimately contributes to the successful and safe deployment of molded rubber components in various applications.