Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

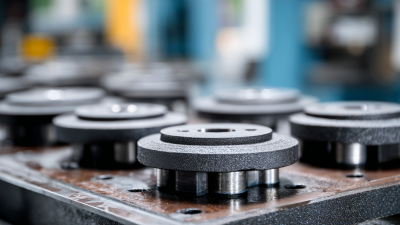

In today's industrial and manufacturing environments, effective vibration control is crucial for protecting machinery, enhancing product quality, and ensuring worker safety. One of the most effective methods for achieving superior vibration isolation is through the use of Rubber Isolators. These specialized components are designed to absorb and isolate vibrations, thereby preventing them from propagating through structures and adversely affecting equipment performance and longevity.

Selecting the right Rubber Isolators is a critical decision that can significantly impact the overall efficacy of vibration control strategies. Factors such as the frequency of vibrations, load capacity, and environmental conditions must be carefully considered to ensure optimal performance. Additionally, the material properties of the rubber, including hardness and damping characteristics, play a vital role in determining the effectiveness of the isolators. By understanding these critical aspects, engineers and designers can make informed decisions that lead to improved operational efficiency and reduced maintenance costs in their facilities.

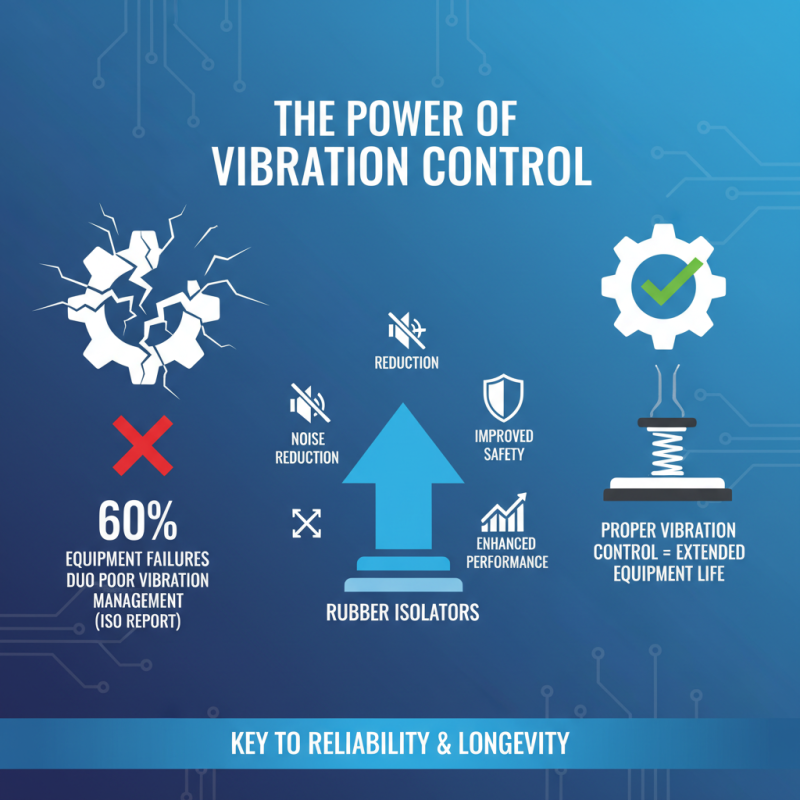

Vibration control plays a pivotal role in various industries, influencing the longevity and performance of machinery and equipment. According to a report by the International Organization for Standardization (ISO), nearly 60% of equipment failures are attributed to inadequate vibration management. This underscores the importance of selecting the right vibration control solutions, such as rubber isolators, to mitigate unwanted vibrations that can lead to mechanical wear, noise pollution, and safety hazards.

In industrial settings, effective vibration control can significantly enhance operational efficiency. A study published in the Journal of Sound and Vibration indicates that implementing robust vibration isolation systems can reduce machinery downtime by as much as 30%, resulting in substantial cost savings. Furthermore, in the context of sensitive environments such as laboratories and hospitals, minimizing vibrations is crucial for maintaining accuracy in measurements and ensuring the safety and comfort of patients. The optimal selection of rubber isolators directly contributes to these critical operational requirements, demonstrating that investing in vibration control is not just beneficial but essential for sustaining high-quality performance across various applications.

When selecting rubber isolators for effective vibration control, it's essential to understand the various types available and their specific functionalities in vibration isolation. Rubber isolators can be classified into several categories, including standard rubber mounts, elastomeric bearings, and reinforced rubber isolators. Each type offers distinct advantages depending on the application and environmental conditions. For instance, standard rubber mounts are widely used in industrial machinery to dampen vibrations, while elastomeric bearings are designed for more dynamic applications, providing greater load-bearing capabilities and flexibility.

According to a report by the Vibration Institute, improper selection of vibration isolation systems can lead to a decrease in equipment performance by up to 30%. The report emphasizes that different rubber isolators exhibit varying stiffness and damping characteristics, which directly impact their effectiveness in isolating vibrations. High-damping rubber isolators are particularly effective in reducing high-frequency vibrations, making them ideal for applications in HVAC systems and sensitive equipment setups. Moreover, advanced compound materials are now being utilized to enhance the durability and performance of these isolators, ensuring prolonged effectiveness even in demanding environments. Understanding these functionalities helps industries select the right rubber isolator to achieve maximum vibration control and improve overall machinery reliability.

When selecting rubber isolators for vibration control, several key factors should be taken into account to ensure optimal performance for your specific application. First, consider the type and frequency of the vibrations that need to be controlled. Different rubber materials and designs have varying abilities to absorb vibrations at specific frequencies. High-frequency vibrations may require stiffer isolators, while softer materials might be more effective for low-frequency applications. Understanding the nature of the vibrations is crucial for making an informed choice.

Another important aspect to evaluate is the load capacity of the rubber isolators. It's essential to match the isolators to the weight and movement of the equipment they will support. Overloading an isolator can lead to premature failure or insufficient vibration isolation. Therefore, calculating the dynamic load and choosing isolators with an adequate safety margin is vital. Additionally, environmental factors such as temperature, humidity, and exposure to chemicals should be considered, as they can significantly affect the performance and longevity of the rubber isolators. By taking these factors into consideration, you can select the right rubber isolators that will provide effective vibration control tailored to your needs.

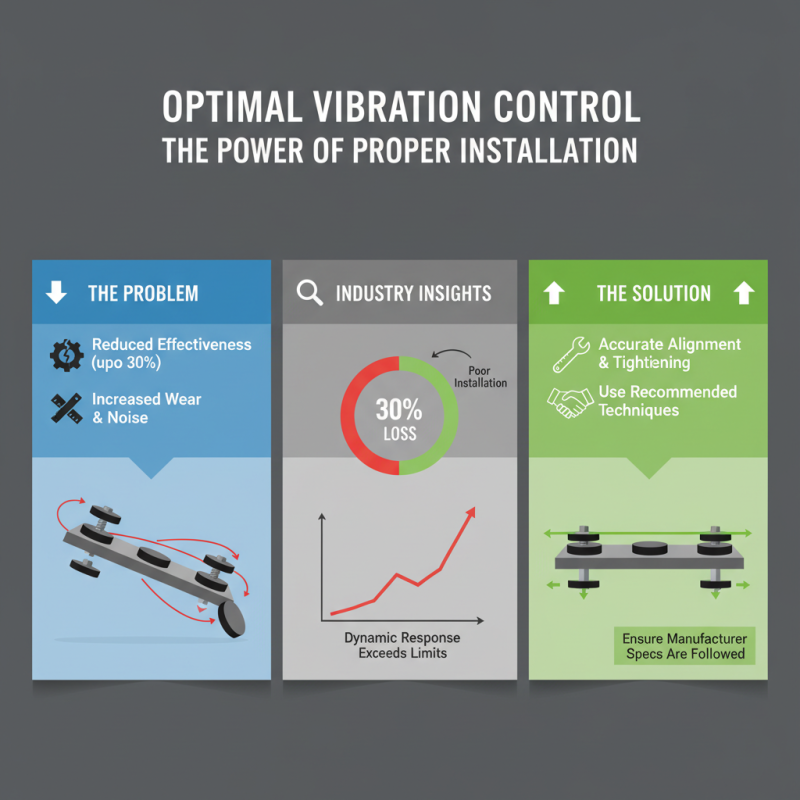

Proper installation of rubber isolators is crucial for achieving optimal vibration control in various applications, from industrial machinery to residential HVAC systems. According to recent industry reports, poorly installed isolators can lead to as much as a 30% reduction in their effectiveness, contributing to increased wear and tear on equipment and amplifying noise pollution. To ensure proper installation, it is important to accurately align and tighten the isolators to the manufacturer's specifications and to use the recommended mounting techniques. Failure to follow these guidelines can result in dynamic responses that exceed the isolators' designed operational limits.

Tips: When installing rubber isolators, always start by cleaning the mounting surfaces to remove debris that can interfere with the isolators' performance. Use a torque wrench to ensure that bolts are tightened evenly, preventing any undue stress on the isolators. Additionally, consider the load characteristics and motion of the equipment; vertical and lateral forces should be accounted for in the isolator selection and positioning.

Another vital aspect of installation is ensuring that the isolators are not compressively overloaded. According to the dynamics analysis conducted by the Vibration Institute, isolators should only be used within their designed load capacity to prevent premature material degradation. Regular inspections post-installation can help identify any shifts or alignment issues that may develop over time, thus maintaining optimal performance.

To maintain the long-term efficiency of rubber isolators, regular inspections are essential. These inspections should focus on checking for signs of wear, degradation, or cracking in the rubber material. Environmental factors such as temperature fluctuations, exposure to chemicals, and UV light can accelerate deterioration. Therefore, it's vital to assess the operating conditions of the isolators frequently and ensure they are not exposed to elements that could compromise their integrity.

Additionally, proper installation plays a crucial role in the performance of rubber isolators. Ensuring that isolators are installed correctly with the appropriate mounting techniques can prevent unnecessary stress and extend their lifespan. Over-tightening or misalignment can lead to premature failure, so it’s crucial to follow the manufacturer’s guidelines meticulously. Applying routine maintenance practices, such as tightening hardware and cleaning the isolators, can also promote their effectiveness and reliability over time.