Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

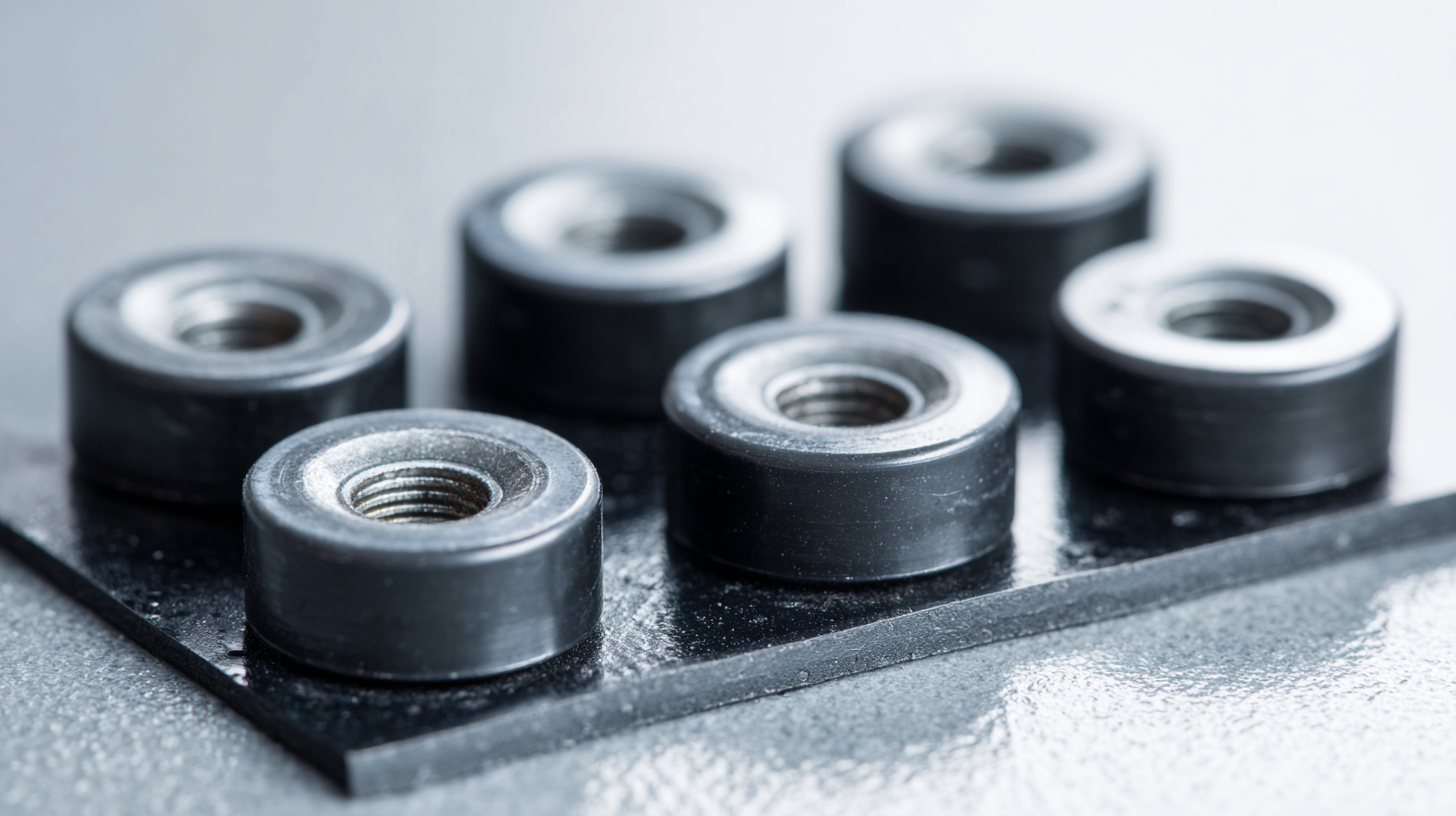

In the realm of product design and manufacturing, the choice of components can significantly impact functionality and durability. Adhesive Rubber Feet, often underestimated in their importance, play a crucial role in protecting surfaces, reducing vibrations, and enhancing user experience.

According to a recent industry report, the global market for adhesive rubber products is projected to grow by over 5% annually, driven by increased demand across various sectors, including electronics, furniture, and automotive industries. Selecting the right adhesive rubber feet not only ensures optimal performance but also prolongs the lifespan of products.

With a myriad of options available, understanding the specific requirements of your project—such as material compatibility, load-bearing capacity, and environmental resilience—is essential.

This guide aims to equip you with the knowledge necessary to make informed decisions, ensuring that you choose the most suitable adhesive rubber feet for your unique applications.

This guide aims to equip you with the knowledge necessary to make informed decisions, ensuring that you choose the most suitable adhesive rubber feet for your unique applications.

When selecting adhesive rubber feet for your projects, understanding the different types available and their specific applications is crucial. Rubber feet come in various materials to suit diverse environments. For instance, silicone rubber feet are favored for high-temperature applications, maintaining their properties up to 300°F. According to a report by the Adhesive and Sealant Council, the demand for silicone-based products is anticipated to grow at a CAGR of 4.5% through 2026, highlighting their popularity in industries ranging from automotive to consumer electronics.

Another commonly used material is EPDM (Ethylene Propylene Diene Monomer), which excels in outdoor and weather-resistant applications. EPDM rubber feet are often employed in garden tools and outdoor furniture to withstand UV radiation and extreme temperatures. Research by Research and Markets predicts that the global rubber products market will exceed $100 billion by 2025, with adhesive rubber feet contributing significantly due to their versatile applications across various sectors, including manufacturing and home improvement. Each type of adhesive rubber foot serves a unique purpose, making it essential to assess the specific requirements of your project before making a selection.

When selecting adhesive rubber feet for your projects, durability is a paramount factor to consider. The type of rubber used can significantly impact the lifespan and performance of the adhesive feet. Look for high-quality materials like silicone or EPDM rubber, which offer superior resistance to wear, temperature variations, and environmental factors. These materials not only enhance scratch resistance on various surfaces but also provide stability under heavy loads.

**Tips:** Before making a purchase, evaluate the intended use of the rubber feet. For items exposed to moisture or chemicals, opt for adhesives specifically formulated for those conditions. Additionally, consider the weight and material of your project; heavier items may require thicker, sturdier adhesive feet to ensure reliable support.

Another critical factor is the adhesive strength. Ensure that the adhesive used in the rubber feet matches the surface you're applying them to. For example, a strong adhesive designed for wood may not perform well on metal or plastic. Testing different adhesives in small sections can help determine which combination provides the best durability for your specific needs.

When selecting adhesive rubber feet for your projects, the adhesive strength is a critical factor that can significantly impact performance. Different projects have varying requirements, and understanding the specific conditions under which the rubber feet will be used is essential. For instance, if your project involves high-temperature environments or fluctuating weather conditions, you'll need adhesive rubber feet that can maintain their grip and flexibility without degrading. Evaluating the composition of the adhesive—the type of rubber and its resistance to environmental factors—will help ensure that the rubber feet will perform optimally.

Moreover, the surface material where the adhesive rubber feet will be applied plays a vital role in their effectiveness. Smooth surfaces, such as glass or metal, often require a different adhesive strength compared to textured or porous materials like wood or fabric. A thorough assessment of the surface's composition and the stress it will endure can guide you in choosing the right adhesive strength. High tack adhesion is critical for projects that demand a permanent bond, while low-tack options might be better suited for temporary applications. Understanding these dynamics will enhance the longevity and reliability of your projects.

| Application | Material Type | Adhesive Strength (N/cm²) | Temperature Resistance (°C) | Durability (Months) |

|---|---|---|---|---|

| Office Equipment | Silicone | 5.0 | 60 | 12 |

| Appliances | EPDM Rubber | 6.5 | 80 | 24 |

| Electronics | Neoprene | 4.0 | 50 | 18 |

| Furniture | TPR (Thermoplastic Rubber) | 7.0 | 70 | 30 |

| Automotive | Viton | 8.0 | 100 | 36 |

When selecting adhesive rubber feet for your projects, understanding industry standards and compliance is essential for ensuring quality and performance. Various standards, such as ASTM and ISO, dictate the material properties, durability, and safety features of rubber feet. Adherence to these standards helps guarantee that the products will perform as expected under specific conditions, such as temperature fluctuations and load-bearing requirements. Compliance also plays a significant role in determining the environmental impact of the materials used, making it crucial for projects that prioritize sustainability.

Additionally, it is vital to consider the certifications and testing procedures the adhesive rubber feet have undergone. Products that have been rigorously tested for factors like adhesion strength, wear resistance, and chemical stability are more likely to meet or exceed user expectations. By choosing adhesive rubber feet that conform to recognized industry standards, you can enhance the reliability of your projects, ensuring that they stand the test of time and usage. Ultimately, prioritizing compliance and quality standards in your selection process will lead to better outcomes in both functionality and safety.

When installing adhesive rubber feet, proper preparation and maintenance are crucial for ensuring their longevity and effectiveness. Begin by thoroughly cleaning the surface where the rubber feet will be applied. This can involve removing any dust, grease, or old adhesive residue to create a smooth, adhesive-friendly surface. Using a mild solvent can enhance adhesion by allowing the adhesive to form a secure bond. For optimal results, it’s advisable to roughen the surface slightly, as this increases the area for adhesion and provides better hold.

Maintenance of adhesive rubber feet involves regular checks to ensure they remain intact and functional. Given the wear and tear that can occur, inspect them frequently for signs of deterioration or detachment. If any rubber feet begin to peel off, it’s important to reapply or replace them promptly to avoid further damage or instability. Understanding the specific application and environment can also influence the choice of adhesive. For projects that require high durability, consider opting for professional-grade rubbers or adhesives that can withstand stress and environmental factors, ensuring the longevity and performance of your projects.