Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

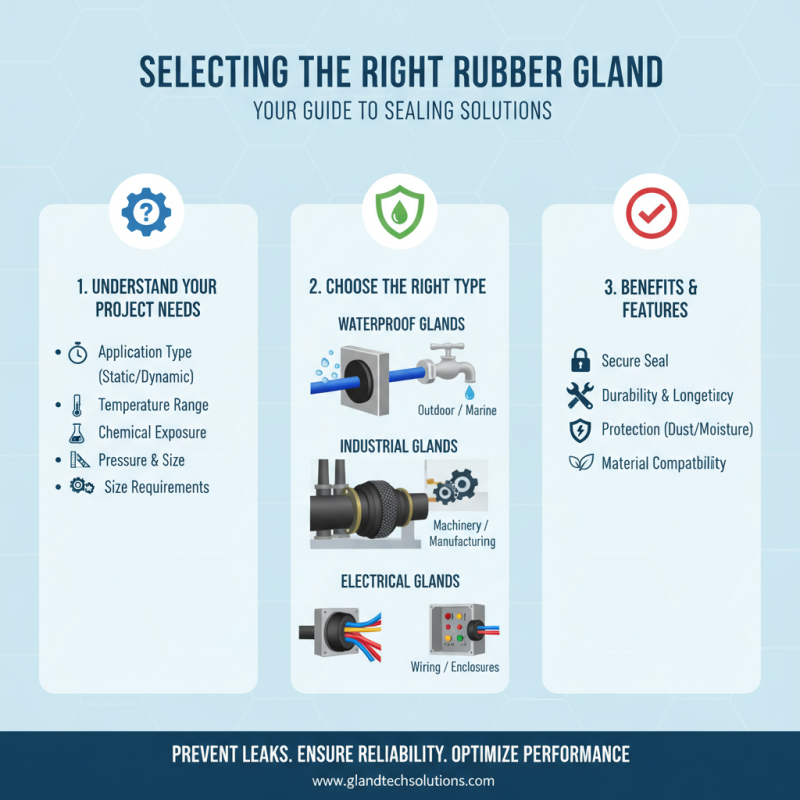

When it comes to selecting the right components for your engineering or construction projects, understanding the various types and functions of materials is crucial. One such component that plays an important role in ensuring the integrity and performance of flexible installations is the Rubber Gland. This versatile fitting is essential for creating watertight seals, protecting electrical connections, and accommodating movement in different applications. With the vast variety of Rubber Glands available on the market, choosing the right one can seem daunting.

Choosing the perfect Rubber Gland requires careful consideration of several factors that pertain to the specific application needs. These factors include the environmental conditions it will be exposed to, the types of cables or pipes it will house, and the mechanical demands of the system. Understanding these variables will guide you in selecting a Rubber Gland that not only fits perfectly but also enhances the longevity and reliability of your installation. This article will explore various aspects to consider when choosing a Rubber Gland, ensuring that you make an informed decision tailored to your project's unique requirements.

Rubber glands are essential components in various applications, serving as protective seals that facilitate the safe passage of cables while preventing the ingress of moisture and contaminants. Understanding their structure and function can help in selecting the right type for your specific needs. Typically, rubber glands are used in electrical installations, providing strain relief and ensuring the integrity of the connection against environmental factors such as dust and water. Their flexibility and durability make them ideal for applications in construction, marine environments, and industrial settings.

When choosing a rubber gland, consider factors such as the diameter of the cables, the environment in which the gland will be used, and the type of sealing required. Different types of rubber materials offer varying levels of resistance to temperature, chemicals, and aging, making it crucial to match the gland material with your application requirements. Additionally, the installation process can vary based on the design of the gland, with some requiring specific tools or techniques to ensure a secure fit. Understanding these basics allows you to make an informed decision that will ensure both functionality and longevity in your applications.

When selecting the right rubber gland for your specific application, several key factors must be carefully evaluated to ensure optimal performance and reliability. First, consider the environmental conditions to which the rubber gland will be exposed. Factors such as temperature fluctuations, exposure to chemicals, and levels of moisture can significantly impact the material's durability and effectiveness. Selecting a rubber compound that can withstand these environmental challenges will help prevent premature failure and ensure a longer lifespan for the component.

Additionally, assess the physical requirements of your application, including the size and shape of the gland, as well as the load it must bear. The compatibility of the rubber gland with other materials in the assembly, such as metals or plastics, is equally important; improper compatibility can lead to failure due to chemical reactions or thermal expansion differences. Lastly, consider the installation method and maintenance needs. Some rubber glands may require more complex installation techniques, while others can be easily integrated into existing systems. By carefully analyzing these factors, you can choose the rubber gland that best meets the functional and environmental demands of your application.

| Factor | Description | Consideration |

|---|---|---|

| Material Type | Different materials offer various properties like heat resistance, chemical resistance, and flexibility. | Consider the environment where the rubber gland will be used. |

| Size | Glands come in various sizes to fit different applications. | Measure the application to ensure a proper fit. |

| Temperature Range | Each rubber type has a maximum and minimum temperature range. | Know the operating temperature conditions of your application. |

| Seal Type | Different seals are designed for different fluid types and pressures. | Select a seal appropriate for the fluid being contained. |

| Durometer Hardness | Measures the rubber's hardness and can affect sealing performance. | Choose hardness based on application requirements, softer for compression, harder for durability. |

| Environmental Conditions | Consider exposure to elements such as UV, ozone, or water. | Select materials that withstand environmental conditions effectively. |

| Compliance Standards | Some applications require compliance with industry standards. | Consult regulations applicable to your industry. |

When selecting the right rubber gland for your application, it's crucial to understand the specific requirements of your project. Different types of rubber glands are designed for various uses, each offering unique benefits and features. For instance, waterproof rubber glands are ideal for electrical applications exposed to moisture, providing a secure seal that prevents water ingress. This makes them indispensable in outdoor installations, marine environments, or any setting where exposure to wet conditions is a concern.

On the other hand, chemical-resistant rubber glands are essential for applications involving harsh chemicals. These glands are made of specialized materials that can withstand corrosive substances, thus ensuring the integrity of the installation over time. In manufacturing and laboratory environments, where the risk of chemical exposure is high, these types of glands provide a reliable solution. Moreover, temperature-resistant rubber glands expand the range of applications by allowing connectors to perform optimally in extreme heat or cold, making them suitable for automotive, aerospace, or heavy machinery uses. Understanding these distinctions will guide you in choosing the most appropriate rubber gland for your specific application.

When selecting a rubber gland for a specific application, assessing material compatibility is crucial to ensure optimal performance and longevity. Different rubber materials come with unique properties that may react differently to environmental factors, chemicals, and mechanical stresses. For instance, certain rubber compounds can swell or degrade when exposed to oils, fuels, or solvents, while others are designed to withstand high temperatures or extreme weather conditions. It is essential to understand the operating environment and fluid interactions to avoid failures that could lead to downtime or costly repairs.

Apart from chemical resistance, organizations must also consider physical properties such as tensile strength, elasticity, and hardness of the rubber material. These factors determine how well the rubber gland can maintain its integrity under mechanical stress and varying temperature conditions. By analyzing the specific demands of the application—paying close attention to factors like pressure, temperature, and exposure to corrosive substances—users can make informed choices about which rubber glands will fulfill their requirements effectively. Compatibility assessments not only enhance performance but also support safety standards, ensuring that the selected materials will not compromise the system's overall reliability.

When selecting the right rubber gland for your application, evaluating the performance standards and certifications is crucial. Rubber glands serve various purposes across different industries, from electrical insulation to fluid sealing, and their efficacy can directly impact safety and functionality. Performance standards often include specific metrics such as tensile strength, temperature resistance, and chemical compatibility. It is essential to understand these parameters to ensure that the chosen rubber gland will meet the demands of its intended environment.

Certifications play a vital role in ensuring that a rubber gland has met industry standards. Look for products that have been tested and certified by relevant organizations, which can provide assurance of quality and reliability. Certifications such as ISO, UL, or other regional requirements can indicate that the product adheres to specific safety and performance benchmarks. By prioritizing products with verified certifications, you can mitigate risks associated with product failure and enhance overall system integrity. This careful evaluation of performance standards and certifications will help you make an informed decision that aligns with your operational requirements.