Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

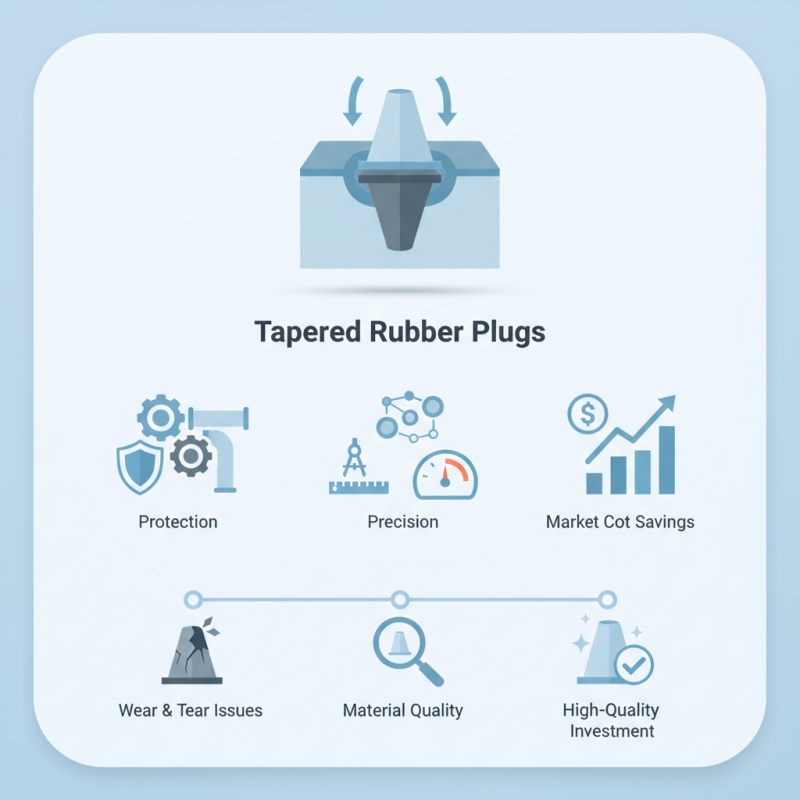

In various industries, Tapered Rubber Plugs have become invaluable tools. These unique plugs offer a versatile solution for sealing, stopping, and protecting various materials and components. According to a recent report by Grand View Research, the global rubber market is expected to reach $41 billion by 2026, highlighting the increasing importance of reliable rubber products.

Tapered Rubber Plugs are particularly effective in applications requiring precision. Their design allows for a snug fit, preventing leaks and ensuring safety across projects. For instance, in plumbing, a tight seal can prevent costly water damage. However, not all plugs perform equally. Users must carefully consider material quality and application to avoid potential failures.

Moreover, while Tapered Rubber Plugs are widely used, there is a need for continuous improvement. Some users report issues with wear and tear over time. This highlights the importance of selecting the right plug based on specific project needs. Investing in high-quality plugs pays off, considering the significant costs associated with replacements and repairs.

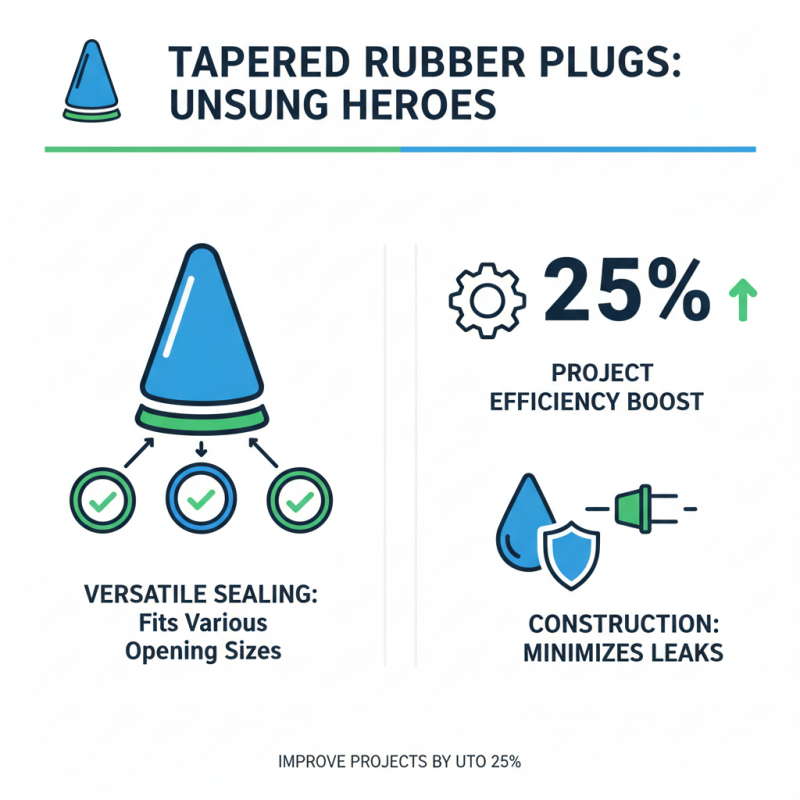

Tapered rubber plugs are often overlooked in project applications. However, their unique design offers significant advantages. These plugs can seal different opening sizes, making them versatile in various industries. In construction, they ensure that surface leaks are minimized. According to industry reports, effective sealing can improve overall project efficiency by up to 25%.

Moreover, tapered rubber plugs are essential for safety in manufacturing. They prevent contamination by blocking off access points. In a report by the National Institute of Standards and Technology, it was noted that proper seals could reduce the risk of product spoilage. Poor sealing methods can lead to financial losses. Some companies still use outdated sealing techniques, risking both safety and efficiency.

In addition, the adaptability of tapered rubber plugs can lead to innovation. When designing a new product, engineers often require different sizes and shapes. Many still rely on standard plugs. This can limit their design options. Modern projects benefit from custom features, allowing for more precise applications. Using tapered plugs can enhance both design flexibility and user safety significantly.

Tapered rubber plugs offer unique advantages compared to traditional sealing methods. Their design allows for a snug fit in various sizes of holes and openings. This versatility makes them ideal for many projects, from plumbing to construction. Unlike rigid seals, these plugs adapt to the shape of the space they fill, ensuring a tighter seal. This adaptability can reduce leaks and other issues.

One of the key benefits of tapered rubber plugs is their ease of use. Installation is simple and quick. You can insert them by hand without needing special tools. They conform well to different surfaces, which helps maintain a reliable seal. However, it’s important to select the right size. A poorly fitted plug can lead to failures or leaks.

When using tapered rubber plugs, consider these tips. Always clean the area before installation. Dust and debris can prevent a good seal. Check for any wear or damage to the plug after use. These checks can help avoid issues in future projects. Ultimately, while these plugs are effective, they require attention to detail to perform well.

When it comes to plugging applications, tapered rubber plugs stand out as an excellent choice. Rubber’s unique properties make it particularly effective in various settings. Its elasticity allows the plugs to conform to different shapes and sizes, creating a reliable seal. Unlike harder materials, rubber minimizes the risk of damage to the surface it contacts.

Rubber is durable yet flexible. This combination makes it suitable for both temporary and permanent sealing solutions. It can withstand different temperatures and resist various chemicals. However, not every rubber plug is created equal. Some may degrade quickly in harsh conditions. It's crucial to choose the right type for specific projects.

Moreover, the texture of rubber aids in grip. This can be vital when inserting or removing the plugs. Yet, improper handling may lead to wear and tear over time. Users often find that frequent replacements are necessary, prompting a reevaluation of their choices. Understanding these material properties helps in selecting the appropriate plug for your needs.

| Property | Tapered Rubber Plugs | Usage Benefits |

|---|---|---|

| Material Flexibility | High | Conforms to irregular shapes |

| Temperature Resistance | -50°C to 100°C | Suitable for various environments |

| Water Resistance | Excellent | Prevents leakage effectively |

| Chemical Resistance | Moderate | Effective for many common chemicals |

| Ease of Installation | Very Easy | Quickly installed by hand |

| Cost | Moderate | Good value for performance |

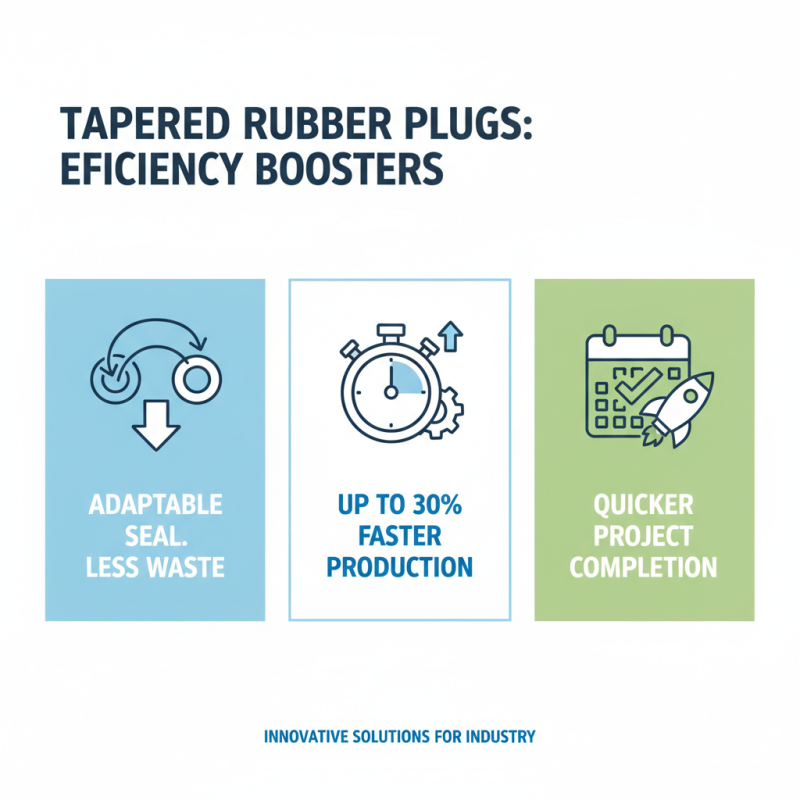

Tapered rubber plugs offer significant efficiency gains across various industries. These plugs adapt to different sizes and shapes, creating a tight seal. This adaptability reduces material waste during projects. In fact, studies show that using these plugs can improve production speed by up to 30%. Fast setup times mean quicker project completion.

Field data supports these benefits. Companies reported fewer leaks and decreased downtime. Projects that utilized tapered rubber plugs completed tasks quicker, leading to increased profitability. Employees found them easy to install and removed, significantly enhancing workflow. However, some users noted they could be challenging in high-pressure situations. Reflecting on these challenges can lead to better usage techniques.

Moreover, user feedback highlights the importance of proper sizing. If the plug doesn’t fit correctly, it may not perform as intended. This issue points to the necessity for careful measurement before selection. Understanding these nuances influences overall project success. Adopting tapered rubber plugs can transform processes, but it requires thoughtful application.

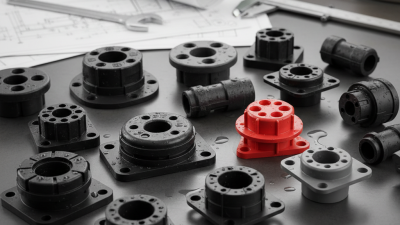

Tapered rubber plugs have diverse applications across industries. In the automotive sector, they are used to seal openings during assembly processes. A report by the International Rubber Study Group reveals that around 15% of rubber consumption is in automotive manufacturing. These plugs ensure that fluids do not leak. They also protect vulnerable components from contaminants.

In construction, tapered rubber plugs serve as effective seals for pipes and fixtures. According to a recent study by IBISWorld, the construction sector relies heavily on rubber products, reflecting a growth rate of 4.5% annually. Plugs prevent debris from entering systems, enhancing longevity. However, improper sizing can lead to gaps. Such flaws risk project timelines.

The medical industry benefits too. Tapered rubber plugs are crucial for laboratory use, sealing vials and test tubes. According to a report from the Global Medical Device Market, this sector is projected to exceed $500 billion by 2025. Materials must meet stringent standards. Yet, variability in production can sometimes compromise safety. Observing these nuances can help optimize the use of rubber plugs effectively.