Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

In the world of sealing solutions, Tapered Rubber Plugs have emerged as a crucial component for various applications, from industrial processes to home improvement projects. Experts in the field highlight the importance of using these plugs effectively to maximize their functionality. According to John Smith, a renowned expert in sealing technologies, "The right use of tapered rubber plugs can significantly enhance sealing efficiency and reduce leaks in any application."

This article will delve into the top 10 tips for using Tapered Rubber Plugs effectively, offering practical advice that can help both professionals and DIY enthusiasts achieve optimal results. Understanding the properties and advantages of tapered designs will not only aid in selecting the right plug for the job but will also ensure that they are applied correctly to avoid common pitfalls.

From choosing the appropriate size and material to proper installation techniques, these tips will empower users to harness the full potential of Tapered Rubber Plugs, leading to improved performance and longevity in various settings. Whether you are in manufacturing, automotive, or simply tackling a home project, mastering the use of Tapered Rubber Plugs can make all the difference in achieving a reliable seal.

When selecting tapered rubber plugs, several essential features should be considered to ensure optimal performance and efficiency. One of the foremost aspects is the material used in the plug. High-quality rubber that is resistant to compression, abrasion, and environmental factors will enhance the durability of the plug. Additionally, consider the flexibility of the material, as it allows the plug to conform more effectively to various fittings and create a better seal. This is particularly important in applications that require precision, as it minimizes the risk of leaks.

Another crucial feature to evaluate is the size range of the tapered rubber plugs. They should be available in various diameters and lengths to accommodate differing opening sizes. A well-designed tapered structure facilitates a snug fit, which is vital for preventing any unintended dislodging during usage. It's also beneficial to look for plugs with a ribbed or textured surface; this can increase friction against the walls of the opening, providing additional grip and stability. Ultimately, choosing tapered rubber plugs with the right combination of materials and design features ensures their effectiveness in a wide range of applications.

| Tip | Description | Key Feature | Benefit |

|---|---|---|---|

| 1. Choose the Right Size | Selecting the appropriate size ensures a tight seal. | Variety of sizes available | Prevents leaks and ensures effective use. |

| 2. Check for Material Quality | High-quality rubber improves durability and performance. | Premium rubber compounds | Enhanced lifespan and reliability. |

| 3. Ensure Proper Insertion | Follow correct insertion techniques to avoid damage. | Tapered design | Easier to insert and remove. |

| 4. Use Alongside Other Sealing Methods | Combining methods can enhance sealing effectiveness. | Compatibility | Greater sealing reliability. |

| 5. Maintain Cleanliness | Ensure surfaces are clean before use for best performance. | Easy to clean | Improved sealing efficiency. |

| 6. Store Properly | Proper storage extends lifespan and maintains integrity. | Space-efficient storage | Prevents deformation. |

| 7. Test Before Usage | Always perform a test run prior to the main application. | Testing capability | Identifies issues early. |

| 8. Replace Worn Plugs | Regularly inspect and replace worn plugs to maintain effectiveness. | Visual wear indicators | Ensures continued performance. |

| 9. Choose the Right Color | Color coding helps identify specific applications or sizes quickly. | Variety of colors | Improved organization. |

| 10. Consult Experts When Necessary | Don’t hesitate to seek advice if unsure about usage. | Access to expert knowledge | Informed decision-making. |

When it comes to achieving maximum seal efficiency with tapered rubber plugs, proper sizing is crucial.

The first step involves measuring the diameter of the opening where the plug will be inserted. A snug fit is essential; if the plug is too small, it may not create an effective seal, leading to leakage. Conversely, if the plug is too large, it may cause damage to the surrounding material or fail to hold firmly in place. Utilizing calipers for precise measurement ensures that you select a plug size that fits the specific requirements of your application.

In addition to diameter, it is important to consider the depth of the opening. Tapered plugs are designed to fit securely by engaging with the walls of the opening, increasing their effectiveness as the taper expands. Be sure to choose a plug that not only matches the diameter but also extends adequately into the opening to create a reliable seal.

When inserting the plug, apply even pressure, and avoid forcing it excessively, as this can lead to deformation of the rubber.

By following these sizing techniques, you can enhance the performance and reliability of tapered rubber plugs in various applications.

When it comes to installing tapered rubber plugs safely, following best practices can significantly enhance both efficiency and safety. First and foremost, ensure that the surface where the plug will be installed is clean and free of any debris or contaminants. A smooth and dry surface allows for better adhesion and a more secure fit, reducing the risk of leaks or failure. Prior to installation, inspect the tapered rubber plug for any signs of wear or damage, as using compromised plugs can lead to unsafe conditions.

During the installation process, apply consistent and adequate pressure while inserting the tapered rubber plug. This not only helps achieve a tight seal but also prevents any accidental slippage that could compromise the integrity of the plug. Furthermore, it's important to ensure that the plug is inserted at the correct angle to avoid any unnecessary strain or deformation of the material. For added safety, consider wearing protective gear such as gloves and goggles to mitigate any potential hazards that may occur during the installation process. These simple yet effective practices will help ensure that your use of tapered rubber plugs is both safe and efficient.

When utilizing tapered rubber plugs, it's crucial to be aware of common mistakes that can hinder their effectiveness. One frequent error is selecting the wrong size of plug for the application. Using a plug that is either too small or too large can lead to leaks or insufficient sealing. It is essential to measure the opening accurately and choose a tapered rubber plug that fits snugly, allowing for optimal performance and preventing any potential issues during use.

Another common mistake is improper insertion technique. Users often overlook the importance of inserting the plug at the correct angle and applying the right amount of force. Forcing the plug into the opening can cause damage to the plug itself or the material it is intended to seal. Instead, one should aim to position the plug gradually, ensuring it seals effectively without excessive pressure. Additionally, failing to clean the surface before insertion can result in poor adhesion and diminished sealing effectiveness. Taking time to prepare the area properly can significantly enhance the performance of tapered rubber plugs.

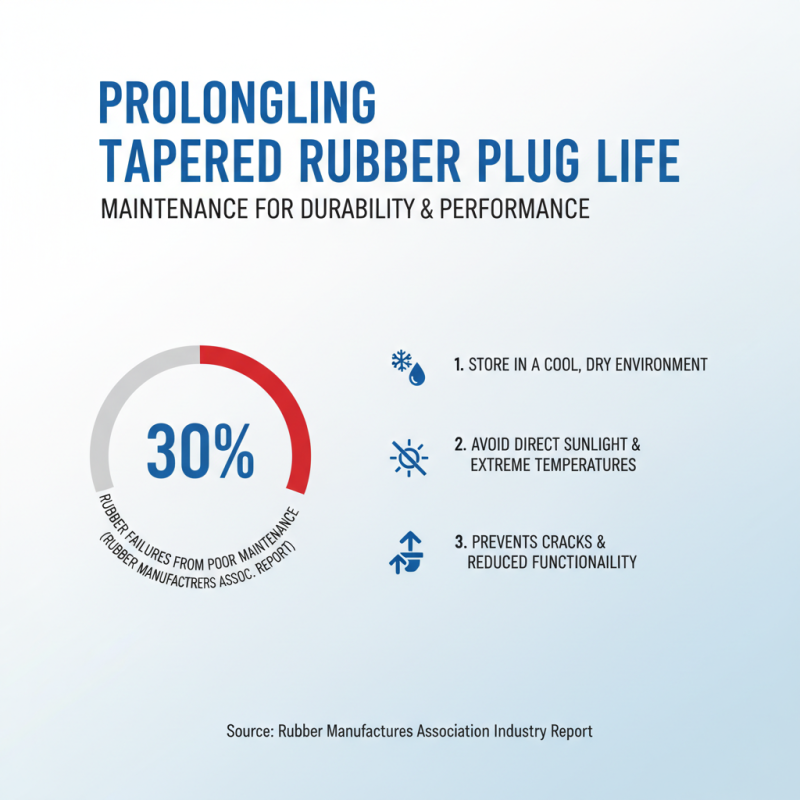

To ensure the longevity and optimal performance of tapered rubber plugs, regular maintenance is key. According to a recent industry report by the Rubber Manufacturers Association, nearly 30% of rubber failures result from inadequate maintenance protocols. One of the most effective strategies to prolong the lifespan of rubber plugs is to store them in a cool, dry environment away from direct sunlight. Exposure to UV rays and extreme temperatures can degrade the rubber material, leading to cracks and reduced functionality.

Moreover, regular inspections are crucial. A study published in the Journal of Polymer Science highlighted that conducting routine checks can help identify early signs of wear and tear. This allows for timely replacements, thereby preventing potential leaks or failures during critical operations. It's also essential to clean the plugs periodically using appropriate solvents that do not harm the rubber compound. Using abrasive materials or harsh chemicals can compromise the integrity of the plugs, shortening their operational life. By implementing these maintenance practices, users can enhance the durability and effectiveness of tapered rubber plugs significantly.