Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

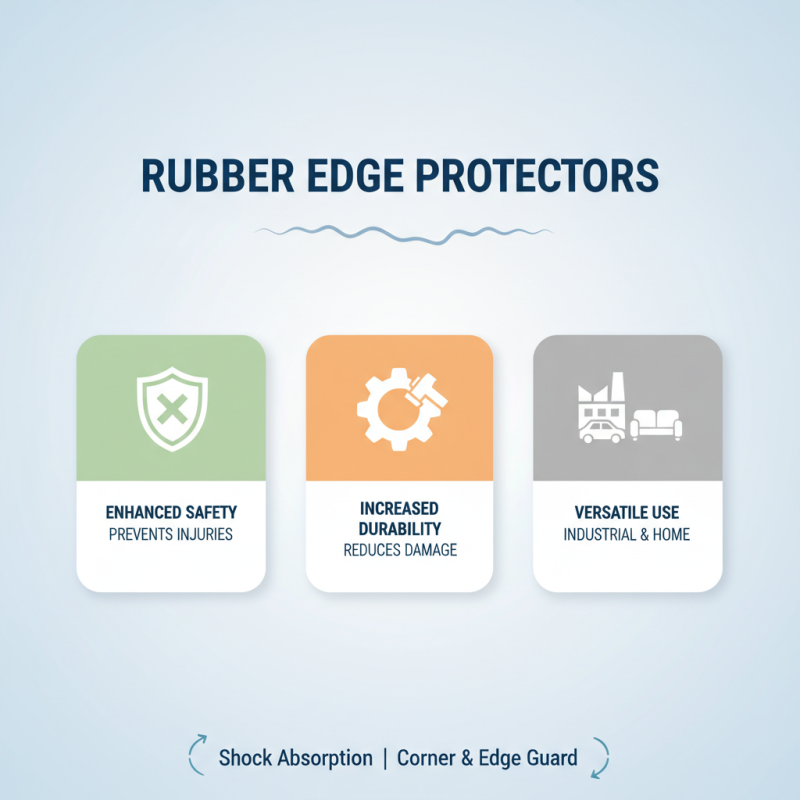

In a world where safety and durability are paramount, the demand for effective protective solutions is ever-increasing. Rubber Edge Protectors have emerged as a crucial product in various industries, providing a strategic safeguard against wear and tear on sharp edges and surfaces. As we step into 2025, it is essential to explore the best options available on the market, ensuring that both residential and commercial spaces are equipped with the right protective measures. According to industry expert Mark Thompson, renowned for his contributions to the field of material safety, "Investing in a high-quality Rubber Edge Protector not only enhances safety but also extends the lifespan of your equipment and surfaces."

As we delve into the intricacies of Rubber Edge Protectors, the importance of selecting the right type becomes clear. These protectors are designed to absorb impacts and mitigate damage, making them ideal for a variety of applications, from industrial settings to home improvement projects. With advancements in materials and technology, the options for Rubber Edge Protectors in 2025 have expanded significantly, offering enhanced performance and versatility.

In this guide, we will examine the top Rubber Edge Protector options available, providing insights into their benefits, applications, and the key factors to consider when making a choice. Whether you are looking to protect furniture, machinery, or construction sites, understanding the landscape of Rubber Edge Protectors will empower you to make informed decisions that prioritize safety and durability.

Rubber edge protectors are essential tools designed to enhance safety and durability in various environments. They effectively prevent damage to edges and corners, which can be particularly beneficial in high-traffic areas or workplaces where equipment and people intersect. These protectors can be found in applications ranging from warehouse shelving to automotive components and even residential furniture, providing shock absorption and safeguarding both the items and individuals from accidental injuries.

When selecting rubber edge protectors, consider the specific use case and the level of impact resistance needed. It's crucial to evaluate the material's durability, flexibility, and ease of installation. For instance, some protectors come with adhesive backing to simplify attachment, while others may require fasteners. Ensuring that the protector fits securely will maximize its protective qualities.

**Tips:**

1. Always measure the edges you want to protect to ensure a snug fit, as improperly sized protectors can lead to inadequate coverage.

2. Look for non-slip surface designs that can help prevent accidental slips or falls in environments where safety is a priority.

3. Regularly inspect the edge protectors for signs of wear or damage to maintain their protective capabilities and ensure long-term safety.

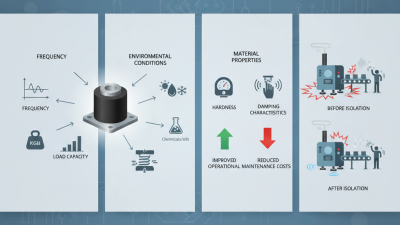

When choosing rubber edge protectors, several key features should be considered to ensure optimal protection and functionality. Firstly, the material composition is crucial; high-quality rubber that is durable and resistant to wear and tear will offer better age resistance and flexibility. Look for options that provide good shock absorption and vibration dampening, especially if the protectors will be used in environments where heavy impacts are likely.

Secondly, the design and shape of the rubber edge protectors play a significant role in their effectiveness. Profiles that fit snugly over edges and corners provide enhanced protection against chipping or damage, preventing injuries. Additionally, some designs feature adhesive backing for easy installation, while others may require mechanical fastening. Lastly, evaluating the thickness and width is important as thicker profiles may offer better protection, but it's essential to balance this with the available space and aesthetic considerations of the application area.

When selecting the best rubber edge protectors for 2025, it's crucial to consider several top brands known for their durability, effectiveness, and customer satisfaction. Many leading brands have developed specialized products that cater to various industries, from construction to automotive. These protectors not only prevent damage to edges but also enhance safety by reducing the risk of injury. Look for brands that emphasize high-quality materials and innovative designs, providing options that fit a range of applications.

In addition to durability, the top brands often offer a variety of styles and sizes to meet specific needs. Whether you require flexible edge protectors for delicate furniture or robust solutions for heavy machinery, reputable manufacturers understand the importance of versatility. Customer reviews and product ratings can provide valuable insights into which brands are trusted by professionals and consumers alike.

Investing in high-quality rubber edge protectors from established brands can ensure long-term protection and value for your projects in the upcoming year.

When selecting rubber edge protectors, it is essential to consider the materials used, as they significantly affect durability and performance. The most common materials include natural rubber, synthetic rubber, and thermoplastic elastomers (TPE). Natural rubber boasts impressive elasticity and tensile strength, making it ideal for environments where shock absorption is essential. However, its susceptibility to UV degradation can limit its outdoor applications.

On the other hand, synthetic rubber, which encompasses a wide range of compounds, provides enhanced durability against environmental factors such as temperature variations and chemical exposure. This makes synthetic options more versatile for industrial and automotive uses. TPE, a newer class of materials, combines the best properties of rubber and plastic, offering excellent flexibility while being fully recyclable. It stands out for its ability to maintain performance across various temperatures and conditions, making it an appealing choice for those looking for sustainable and long-lasting edge protection solutions. Ultimately, the choice of material will depend on specific application requirements, including the environment and types of surfaces involved.

When selecting rubber edge protectors, proper installation is crucial for achieving optimal performance. The efficacy of these protectors can significantly decline if not fitted correctly, leading to increased wear and tear on surfaces. According to industry reports, improperly installed edge protectors can reduce their lifespan by up to 30%, resulting in additional replacement costs and potential safety hazards. Therefore, understanding the installation process is essential for maximizing their benefits.

To install rubber edge protectors effectively, first, ensure that the surface is clean and dry. Any dust or moisture can interfere with adhesion, leading to a failure in securing the protector. It is recommended to use a mild cleaning solution followed by thorough drying. Additionally, it’s important to measure accurately and cut the edge protectors to the desired length before proceeding with installation. Utilizing a heat gun can help make the rubber more pliable, allowing for a better fit around corners and curves.

Another tip to enhance performance is to allow the adhesive to cure properly. Many products require a specific curing time before they can bear weight or experience regular wear. Rushing this process can lead to premature detachment. Monitoring temperature and humidity during the curing phase can further improve adhesion, as most adhesives perform best under specified conditions. Following these guidelines will ensure that your rubber edge protectors last longer and provide the protection that is designed for.