Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Vibration control is essential in many industries. One effective solution is the use of Rubber Isolation Mounts. These mounts reduce noise and vibrations from machines. They protect sensitive equipment and improve overall performance.

Rubber Isolation Mounts come in various designs. Each type serves specific needs. Choosing the right mount is crucial. It can make a significant difference in effectiveness. Sometimes, users may overlook important specifications. This can lead to unsatisfactory results.

The market offers many options for Rubber Isolation Mounts. However, not all mounts deliver the same quality. It's important to analyze features like load capacity and damping. Finding the best mounts may require time and research. Yet, this effort can lead to better outcomes. Investing in quality Rubber Isolation Mounts can enhance productivity.

Rubber isolation mounts play a crucial role in vibration control solutions. These mounts absorb vibrations, reducing noise and enhancing equipment lifespan. They are often used in industrial settings, machinery, and even vehicles. Choosing the right mount can be challenging, as each application has specific requirements.

Consider the load capacity of the mount. A mount might be too weak and not support the equipment. Sometimes, the right choice can be overlooked due to simple oversights. Environmental factors also come into play. Certain rubber materials degrade faster in extreme conditions. Users should evaluate their environment carefully.

Installation is another critical aspect. Proper alignment can be tricky. If the mount isn’t installed correctly, vibrations can increase. This highlights the need for thorough testing after installation. Many neglect this step, leading to persistent issues. Reflecting on these details can help improve vibration control solutions through effective use of rubber isolation mounts.

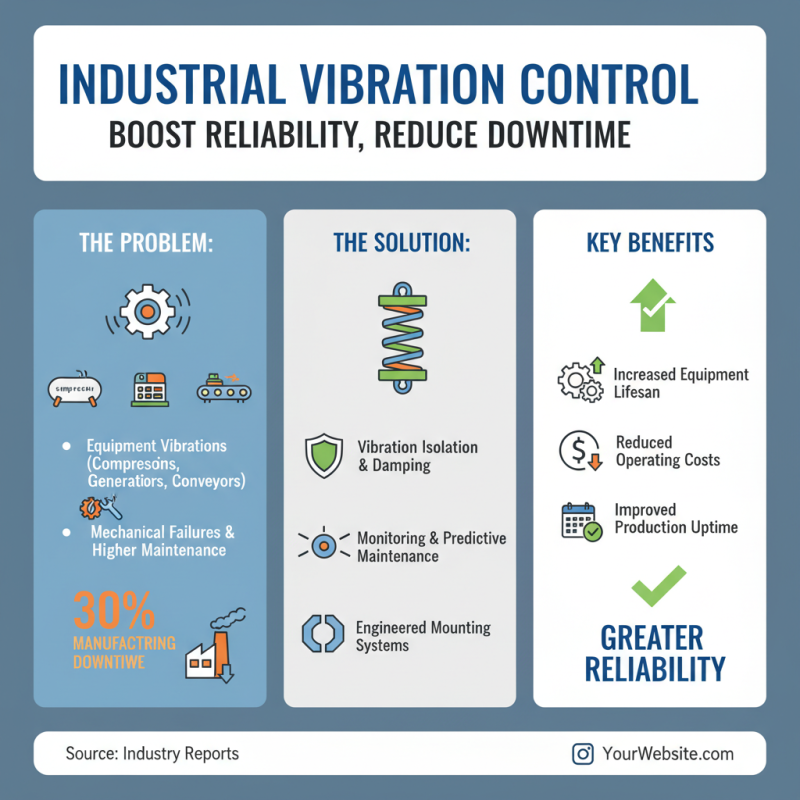

Vibration control plays a crucial role in industrial settings. Equipment like compressors, generators, and conveyors emit vibrations during operation. These vibrations can lead to mechanical failures and increased maintenance costs. Industry reports show that machinery failures caused by vibrations can result in 30% of downtime in manufacturing facilities.

Effective vibration isolation helps mitigate these issues. Rubber isolation mounts are popular in various applications. They absorb shock and reduce noise. A study indicated that proper vibration control can extend equipment lifespan by up to 50%. However, many industries still underestimate this necessity. Poor vibration management can lead to worker safety hazards and reduce productivity.

Choosing the right rubber mounts is essential. Factors like load capacity and frequency should be considered. Over the years, the industry has evolved. Yet, awareness about vibration control remains low. Many companies hesitate to invest in improved solutions. This could lead to regrettable consequences. Advanced options are available, but barriers persist. As such, regular assessments of equipment and their operation can reveal significant opportunities for improvement.

When selecting rubber isolation mounts for vibration control, several criteria are crucial. The first aspect is material durability. High-quality rubber can endure repeated stress and various environmental conditions. According to the Vibration Institute, durable materials reduce maintenance costs by as much as 30%.

Another essential criterion is the load capacity. Isolation mounts must support the weight of the equipment effectively. The American Society of Mechanical Engineers (ASME) recommends a safety factor of at least 2. This ensures mounts can handle unexpected loads. Failure to consider load capacity can lead to equipment damage or operational failures, which can be costly.

**Tips:** Always check load ratings before making a selection. Testing mounts in real-world conditions can reveal insights.

Finally, consider the frequency response. Different mounts perform variably across frequencies. For example, softer mounts may be effective at low frequencies but inadequate at higher frequencies. Balancing performance across the spectrum is key for optimal solutions.

**Tips:** Consult technical specifications for frequency data. Look for mounts that can handle a range of frequencies.

When considering vibration control, choosing the right rubber isolation mount is crucial. Many options exist, but not all perform equally well. Factors to consider include load capacity, frequency response, and environmental resistance. Some mounts excel at isolating low-frequency vibrations, while others perform better with higher frequencies. This diversity creates a challenge for those seeking the best solution.

In our analysis, we looked at five standout mounts. Each offers unique benefits and limitations. One option is ideal for heavy machinery, ensuring minimal movement during operation. Another excels in lightweight applications, providing adequate isolation without excess bulk. However, certain mounts may fail under extreme conditions, such as temperature fluctuations or exposure to chemicals. This highlights the need for careful selection based on specific requirements.

Moreover, installation can also pose issues. Some mounts are straightforward, while others demand precise alignment. This can lead to installation errors, affecting overall performance. It's essential to understand both the benefits and the potential drawbacks. Reflecting on your specific needs will help in making a more informed choice.

Vibration isolation is crucial in various industrial applications. For example, rubber isolation mounts are widely used in manufacturing, construction, and automotive sectors. These mounts help control vibrations, enhancing equipment longevity and performance. According to industry reports, effective vibration control can reduce machine wear by up to 30%.

When selecting rubber isolation mounts, consider performance metrics like dynamic stiffness and load capacity. For many applications, a dynamic stiffness of 15-30 psi is optimal. However, some environments may require mounts with higher load capacities, especially in heavy machinery. It’s essential to analyze the specific needs of each application before making a decision.

Despite advancements, not all rubber mounts perform equally. Some may fail to isolate vibrations adequately, leading to increased noise and equipment failure. Regular evaluation of isolation performance is necessary. Monitoring performance metrics ensures that the chosen rubber mounts meet the required standards. Adapting to new data and feedback can improve outcomes significantly.

| Model | Load Capacity (lbs) | Frequency Range (Hz) | Damping Ratio | Applications |

|---|---|---|---|---|

| Model A | 1000 | 5-50 | 0.2 | Industrial Equipment |

| Model B | 2000 | 10-60 | 0.15 | HVAC Systems |

| Model C | 1500 | 8-45 | 0.25 | Robotics |

| Model D | 1200 | 7-55 | 0.18 | Manufacturing |

| Model E | 1800 | 10-70 | 0.3 | Transportation |

This article delves into the significance of rubber isolation mounts as essential components for effective vibration control in various industrial applications. It outlines the key criteria for selecting the most efficient rubber isolation mounts, emphasizing their role in enhancing machinery performance and reducing wear and tear.

A comparative analysis of the top five rubber isolation mounts is presented, highlighting their specific features and performance metrics relevant to different industry applications. Furthermore, the article discusses emerging trends in rubber isolation mount technologies, exploring innovations that could shape the future landscape of vibration control solutions, ultimately ensuring better operational efficiency and equipment longevity.