Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

When it comes to ensuring the longevity and performance of sensitive equipment, the importance of Rubber Shock Mounts cannot be overstated. According to industry reports, improperly mounted equipment can experience up to a 25% decrease in operational efficiency, leading to costly repairs and maintenance. Rubber Shock Mounts serve as a critical line of defense against vibrations and shocks that can adversely affect not only the machinery but also the overall workflow. With advancements in materials and engineering techniques, the market for these mounts is projected to grow substantially, with a forecasted increase of 15% annually through 2025.

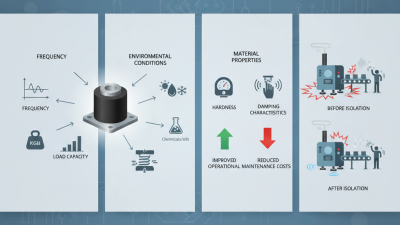

Choosing the right Rubber Shock Mounts for your specific applications requires careful consideration of various factors such as load capacity, frequency response, and environmental conditions. Recent studies have indicated that using appropriately engineered shock mounts can reduce vibration levels by as much as 80%, significantly enhancing equipment performance and reliability. This guide aims to provide you with the top ten tips for selecting the best Rubber Shock Mounts tailored to your unique needs, ensuring optimal performance and durability in every application.

Rubber shock mounts are essential components designed to isolate vibrations and reduce noise in various applications, particularly in audio recording and engineering environments. These mounts function by absorbing and dissipating any mechanical energy generated by surrounding equipment, thereby preventing it from transferring to sensitive devices. The primary purpose of rubber shock mounts is to enhance sound quality by minimizing noise interference, creating a cleaner and more professional audio output.

The effectiveness of rubber shock mounts depends on several factors, including material composition, size, and design. Rubber, due to its inherent elasticity and damping properties, is the material of choice for shock mounts. When selecting the right shock mount for your needs, it's crucial to consider the specific weight and dimensions of the equipment, as well as the type of vibrations encountered in your environment. By understanding the functionality of rubber shock mounts, users can make informed decisions that significantly impact performance and audio clarity, ensuring a more refined and enjoyable experience in sound capture or reproduction.

This bar chart illustrates the importance score of various factors to consider when choosing rubber shock mounts, ranging from durability to warranty. Each factor is rated from 1 to 10 based on its significance in ensuring optimal performance.

When selecting rubber shock mounts, it’s essential to consider various key factors to ensure you choose the best option for your specific needs. First and foremost, the load capacity is critical. You must assess the weight and vibration levels of the equipment you plan to mount. This will help you determine the appropriate size and strength of the shock mount you require.

Another important factor is the material composition of the rubber used in the shock mounts. Different types of rubber can offer varying levels of shock absorption and durability. Look for mounts that provide sufficient flexibility and resilience to withstand regular use while minimizing wear and tear.

Additionally, consider the mounting style and design. The ease of installation and the compatibility with your equipment will greatly impact your overall experience. Opt for designs that allow for quick and hassle-free mounting while ensuring a secure connection.

Tip: Always consult the specifications and user guides for any compatibility notes. Assess the environmental factors as well; for instance, if the mounts will be exposed to extreme temperatures or chemicals, you might need specialized materials. Prioritizing these considerations will lead you to the right rubber shock mounts that effectively meet your operational demands.

| Tip Number | Key Factor | Description |

|---|---|---|

| 1 | Material Quality | Ensure the rubber used is of high quality for durability and performance. |

| 2 | Durometer Rating | Select a durometer rating that meets the specific vibration and shock absorption needs. |

| 3 | Size and Fit | Ensure the shock mounts fit well with your equipment to maximize effectiveness. |

| 4 | Load Capacity | Check the load capacity to ensure it can support your equipment weight. |

| 5 | Installation Ease | Look for designs that are easy to install and require minimal tools. |

| 6 | Environmental Resistance | Consider rubber that withstands environmental factors like heat and moisture. |

| 7 | Price vs. Value | Balance between cost and the performance benefits offered by the mounts. |

| 8 | Noise Reduction | Choose mounts that provide effective noise isolation in addition to shock absorption. |

| 9 | Design and Aesthetics | Consider the visual appeal and how well the designs integrate with your equipment. |

| 10 | User Reviews | Read customer feedback to gain insights about performance and quality. |

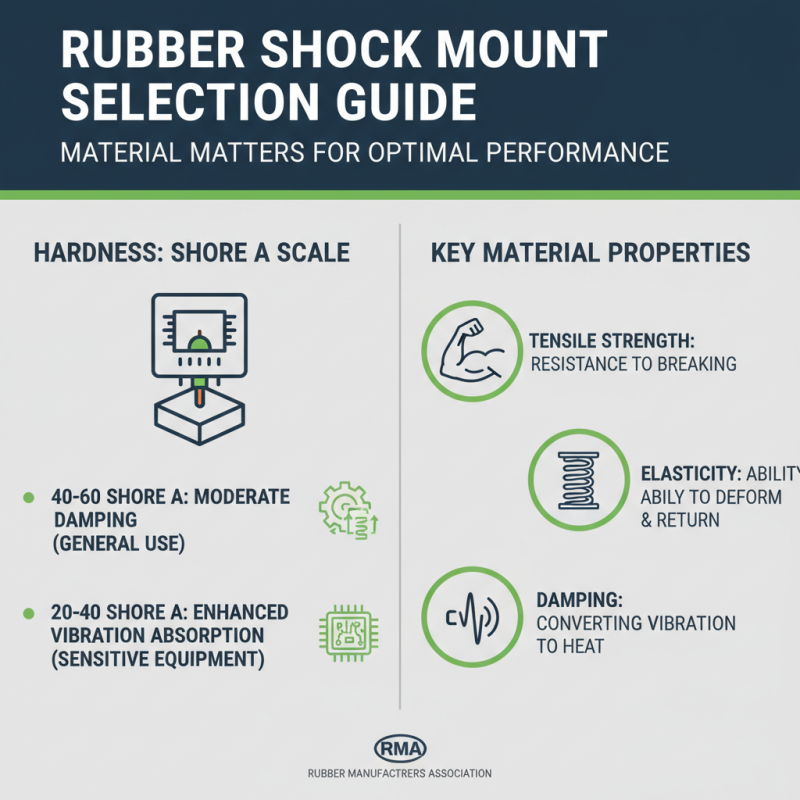

When selecting rubber shock mounts, understanding material specifications is crucial for achieving optimal performance tailored to your specific needs. Various formulations of rubber exhibit unique properties such as hardness, tensile strength, and elasticity. According to the Rubber Manufacturers Association, the Shore A hardness scale, commonly used to measure rubber hardness, suggests that mounts with a hardness range of 40-60 Shore A are suitable for applications requiring moderate damping, while softer mounts (20-40 Shore A) provide enhanced vibration absorption, ideal for sensitive equipment.

Furthermore, the chemical composition of rubber varies significantly among different types, impacting its resistance to environmental factors like temperature, UV light, and ozone. For instance, ethylene propylene diene monomer (EPDM) rubber is renowned for its excellent weather resistance and durability under extreme conditions, making it a preferred choice for outdoor applications. A report from the International Rubber Study Group indicates that the performance of shock mounts can improve by up to 30% when selecting the right type and formulation of rubber based on the expected vibration frequencies and load conditions. Hence, a thorough analysis of these material specifications is essential for ensuring the longevity and effectiveness of your shock mounting solutions.

When selecting rubber shock mounts, assessing their compatibility with your equipment and installation requirements is crucial. Typically, the performance of shock mounts is influenced by factors such as load capacity, frequency range, and damping characteristics. According to a study by the International Institute of Noise Control Engineering, improperly matched shock mounts can reduce the overall effectiveness of vibration isolation systems by up to 50%. Therefore, ensure that the specifications of the shock mounts align with your equipment's weight and operational frequencies to maximize performance.

When it comes to installation, consider the type of mounting interfaces available and whether they meet your structural requirements. Some shock mounts feature universal mounting options that facilitate easier integration with varied equipment setups. Additionally, ensure that the installation method aligns with the intended use; for instance, direct mounting may suit heavy machinery, while softer mounts may be beneficial for sensitive electronic devices. An industry survey by the Vibration Institute indicates that nearly 70% of installation failures stem from mismatched mounts, emphasizing the importance of thorough evaluation.

When considering options, remember these tips: always evaluate the expected load and motion to choose a mount that can handle the specific demands without compromising performance; opt for mounts made of materials that provide the necessary resilience while minimizing wear over time; and consult with industry professionals to gain insights on the best practices for your unique installation scenario.

When selecting rubber shock mounts, cost-effectiveness is a key consideration that can significantly impact both performance and budget management. A recent industry report highlights that high-quality shock mounts, while more expensive upfront, lead to substantial savings over time due to their durability and superior performance. According to a survey by the Audio Engineering Society, professionals indicate that investing in quality mounts can reduce maintenance costs by up to 30%, as they experience less wear and tear and provide better vibration isolation. This emphasizes that spending a little more initially can ultimately safeguard your equipment and reduce long-term expenses.

In addition to durability, the importance of compatibility with your existing systems cannot be overstated. A cost-effective shock mount not only fits within your budget but also enhances the overall functionality of your setup. Industry analysis suggests that mismatched mounts can lead to failures, needing replacements or adjustments that could cost 15-20% of your total audio equipment budget. Therefore, balancing cost with the right specifications is crucial in making a wise investment. By closely evaluating both the immediate financial outlay and the potential long-term savings, users can find suitable shock mounts that meet their operational needs without sacrificing quality.