Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

Rubber suction cups play a vital role in various industries, offering innovative solutions since their inception. These small yet powerful devices have been used in countless applications, from household items to industrial machinery. According to a study by Market Research Future, the global rubber suction cup market is projected to grow significantly, driven by increasing demand in sectors such as automotive and consumer electronics. Expert Mark Thompson, a leading authority in suction technology, once remarked, “The versatility of the rubber suction cup is unmatched in the industry.”

However, as the industry evolves, some challenges remain. For instance, not all rubber suction cups are created equal. Users often encounter issues like insufficient suction or material degradation over time. This inconsistency can lead to frustration and inefficiencies. Businesses must consider the right material and design for their specific needs. Understanding the characteristics of rubber suction cups is crucial for optimizing their application.

Given their broad usage, it is essential to explore the top 10 uses for rubber suction cups. Recognizing their potential can lead to improvements in both everyday tasks and industrial processes. Despite their simplicity, these tools can revolutionize operations when used correctly. It’s a constant learning journey to maximize their effectiveness and address their limitations.

Rubber suction cups are versatile tools used across various industries. They provide reliable attachment and support in numerous applications. According to a report by MarketsandMarkets, the global suction cups market is projected to grow at a CAGR of 5.1% by 2025. This growth underscores their importance in sectors like manufacturing, automotive, and healthcare.

In manufacturing, these cups facilitate the handling of glass, ceramics, and metal sheets. Their ability to create a strong vacuum ensures safe movement without costly damage. In the automotive industry, suction cups lift heavy components during assembly. Precision is vital here. A small failure could lead to production delays or accidents. Statistics show that improper handling can increase costs by 20%.

Healthcare also benefits from suction cups, particularly in medical devices. They hold sensors in place, providing accurate readings. However, issues still arise with temperature sensitivity and adhesive longevity. A study revealed that 15% of medical professionals reported challenges in suction cup performance under various conditions. This data emphasizes the need for ongoing improvements in materials used for suction applications.

Rubber suction cups are often underestimated in their versatility. They can solve many everyday household challenges. For instance, they excel at organizing clutter. By attaching them to walls or shelves, you can hang tools or utensils conveniently. This not only saves space but also keeps items visible and accessible.

Another innovative use is in the kitchen. These cups can hold bowls or cutting boards in place while you chop or mix ingredients. This stability can prevent accidents and make cooking more enjoyable. However, it’s crucial to ensure they are clean and in good condition. A worn-out cup may slip, leading to messy spills.

In bathrooms, suction cups can securely hold toiletries. They can keep items off the counter, creating a neater appearance. However, moisture can weaken their grip over time. Regular checks are essential to maintain their effectiveness. Remember, even the most useful tools need proper care to function well.

| Use Case | Description | Benefits |

|---|---|---|

| Bathroom Essentials | Secure toiletries and shower items on tiles. | Prevents clutter and spills. |

| Kitchen Tools | Hold measuring cups, spoons, and gadgets securely. | Enhances safety and efficiency while cooking. |

| Child Safety | Attach toys or tools to tables or walls. | Reduces the likelihood of accidents. |

| Hanging Artwork | Mount lightweight frames without nails. | Preserves walls and allows easy repositioning. |

| Glass Placement | Hold glass panels in place during installation. | Ensures accuracy and safety throughout the process. |

| Display Items | Showcase small items in craft or store displays. | Creates an appealing presentation. |

| Car Accessories | Mount devices like GPS or phones securely. | Improves driving safety and convenience. |

| Suction Camera Mounts | Attach cameras to various surfaces for photography. | Enhances creativity and stability in shots. |

| Tool Organization | Secure tools in garages or workshops. | Keeps workspace tidy and efficient. |

| Miscellaneous Uses | Attach various items for easy access. | Promotes versatility in home organization. |

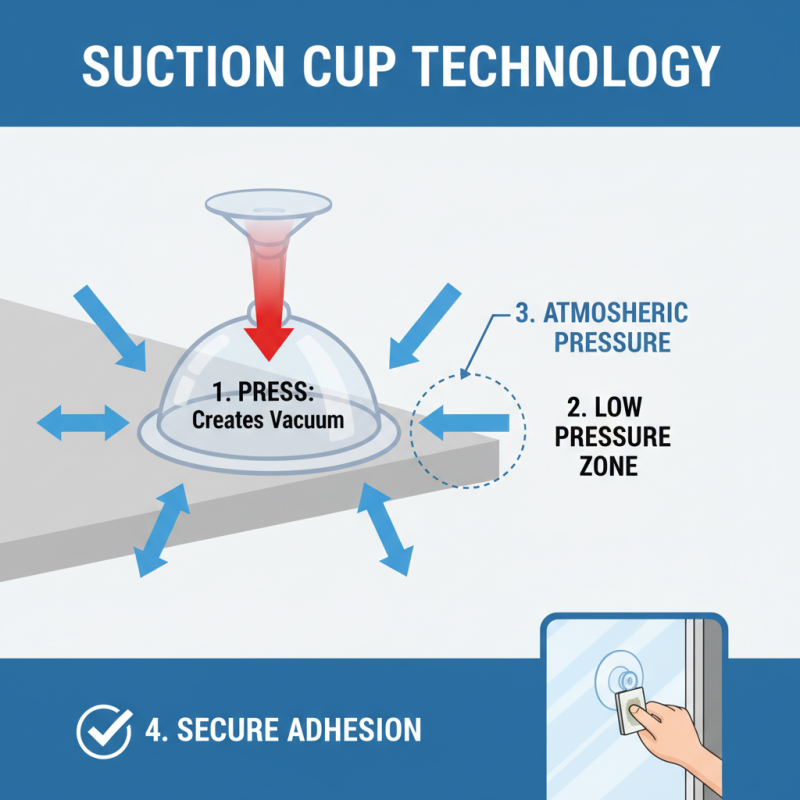

Suction cup technology is fascinating. It relies on the principles of atmospheric pressure and adhesion. The weight of an object creates a vacuum when pressed against a surface. The space between the cup and the surface becomes a low-pressure area. Atmospheric pressure pushes the cup against the surface, securing it firmly.

According to a report by the International Society for Adhesion and Adhesives, suction cups can hold objects weighing up to 80 pounds under optimal conditions. However, performance varies significantly based on surface texture and cleanliness. A dirty or uneven surface can lead to failure. Interestingly, a study from the Journal of Polymer Science highlighted that materials like silicone tend to perform better than others.

Despite their effectiveness, there are limitations. Temperature can affect suction. High heat may weaken the materials, while cold can make them brittle. Users often overlook these factors, leading to disappointing results. Thus, understanding the science behind suction cups is essential for maximizing their utility. Awareness of these nuances can enhance product safety and reliability.

The demand for rubber suction cups in manufacturing has seen significant growth recently. According to a report by Market Insights, the global rubber suction cup market is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This surge reflects the broader trend of automation in industries. Manufacturers are increasingly integrating rubber suction systems for enhanced efficiency.

The versatility of rubber suction cups makes them a preferred choice across various applications. In the automotive sector, they are crucial for handling glass or delicate components. The packaging industry relies on them for precise placement of products. However, adoption can be slow due to misconceptions about durability. Some companies worry that rubber won't withstand heavy loads. Yet, advancements in materials technology have improved strength and longevity.

Challenges persist in maintaining a consistent supply chain for these components. Fluctuations in rubber prices can impact production costs. Additionally, companies may struggle with finding reliable suppliers. Fostering strong supplier relationships is vital. Manufacturers must navigate these complexities to optimize their operations. Balancing cost and quality remains a critical focus for producers.

Rubber suction cups are popular for their versatility and ease of use. When evaluating their performance, safety and durability are crucial factors. The suction cups must maintain a strong hold under varying conditions. They can be used on numerous surfaces, but not all surfaces are suitable. For best results, surfaces should be clean and dry. This is often overlooked, leading to potential hazards.

Durability is another concern. Quality rubber can withstand varying temperatures and pressures. However, some suction cups may wear out quickly, especially with frequent vibrations. It's important to inspect them regularly. Users should be aware of signs of wear and consider replacement if they notice any deterioration. This simple act can prevent accidents.

Safety is paramount in practical applications. If a suction cup fails, it can cause damage or injury. Therefore, knowing the limits of these cups is essential. They may not grip well on porous materials or rough surfaces. This limitation can lead to unexpected failures. While rubber suction cups are quite useful, being mindful of their limitations will ensure better, safer performance.