Get a custom solution for free

-

Phone

-

E-mail

-

Whatsapp

-

Wechat

In industrial settings, adhesive rubber feet play a critical role in minimizing vibrations, preventing slippage, and safeguarding surfaces from scratches and damage. Their application extends beyond industry, infiltrating home environments to improve furniture stability and protect flooring. The concept of combining utility with aesthetics has made these products increasingly popular among consumers seeking both form and function.

As we delve deeper into the versatility of adhesive rubber feet, it becomes evident that their benefits are far-reaching. From machinery and equipment to furniture and gadgets, these small, unassuming components deliver significant impacts, showcasing the essential role they play in both everyday moments and industrial operations.

Adhesive rubber feet are becoming increasingly popular in various home applications, appreciated for their unique benefits. According to a report by ResearchAndMarkets.com, the demand for rubber feet has surged in residential furniture design, with an expected growth rate of 6.8% annually until 2025. These versatile tools prevent scratches and scuffs on floors while adding a non-slip surface that enhances stability. For instance, placing adhesive rubber feet on chair legs not only protects hardwood floors but also mitigates noise during movement, making them essential for homes with multiple occupants.

Furthermore, the customization options offered by adhesive rubber feet are remarkable. The flexible nature of rubber allows manufacturers to produce various sizes, shapes, and textures to suit different household items. Industry experts at Freedonia Group have indicated that the home appliance sector is particularly benefiting from this, as the use of adhesive rubber feet can improve user experience by enhancing grip and durability. In kitchens and workshops, where equipment can encounter moisture and heavy usage, rubber feet provide a dependable barrier that prolongs the lifespan of appliances.

| Application Area | Material Type | Size (mm) | Load Capacity (kg) | Key Benefits |

|---|---|---|---|---|

| Furniture | Natural Rubber | 20 | 5 | Non-slip, Protects floors |

| Electronics | Silicone | 15 | 3 | Heat resistant, Vibration dampening |

| Bathroom Fixtures | EPDM Rubber | 25 | 7 | Waterproof, Durable |

| Industrial Equipment | Neoprene | 30 | 10 | Chemical resistant, Stable |

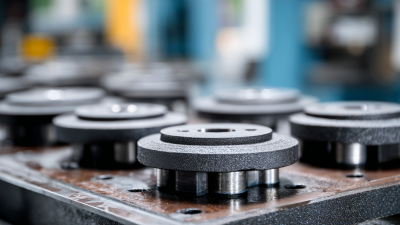

Adhesive rubber feet have emerged as essential components across various industrial applications, significantly enhancing equipment performance. Their versatility makes them invaluable in minimizing vibrations, providing stability, and reducing slippage in machinery. By effectively dampening sound and absorbing forces, adhesive rubber feet help maintain the integrity of sensitive equipment, thus prolonging lifespan and improving operational efficiency. Industries such as manufacturing, automotive, and heavy machinery increasingly rely on these components to meet the demanding performance standards essential for modern operations.

In addition to conventional uses, innovative materials are being explored to further enhance the functionality of adhesive rubber feet. Recent advancements in applied materials, similar to shear thickening fluids used in protective sports gear, may inspire developments in rubber formulations, enabling better adaptability to varied conditions. As industries continue to prioritize performance and safety, integrating advanced materials into adhesive rubber feet will likely play a critical role in future applications, paving the way for more resilient and multifunctional industrial solutions.

When selecting the right adhesive rubber feet for your needs, it is essential to consider several key factors. First, the material composition plays a crucial role in determining the durability and functionality of the feet. High-quality rubber blends provide excellent shock absorption and grip, making them suitable for both home and industrial applications. Additionally, the surface texture can impact the effectiveness of the adhesive; smoother surfaces may require more specialized adhesives to ensure proper bonding.

Another critical aspect is the size and weight capacity of the rubber feet. Depending on the objects they will support, you should select feet that can handle the weight without compromising their integrity. It's also important to assess the environmental conditions they will be exposed to, such as temperature fluctuations, moisture, and exposure to chemicals, as these factors can affect performance and longevity. By carefully evaluating these elements, you can make an informed decision that meets your specific requirements, ensuring optimal performance and protection for your surfaces and equipment.

Adhesive rubber feet are incredibly versatile tools that can transform DIY projects, both at home and in industrial settings. According to a report by Market Research Future, the global rubber product market, which includes items like adhesive rubber feet, is expected to grow significantly, reaching a value of over $60 billion by 2025. This growth is driven by the increasing demand for durable and multi-functional materials, highlighting the importance of such seemingly simple items.

In DIY projects, adhesive rubber feet serve numerous purposes. They can be used to stabilize furniture, preventing slips and scratches while providing effective leveling on uneven surfaces. Their non-slip properties are particularly useful in kitchen and workshop environments where safety is paramount. Additionally, creative uses extend to crafting, where they can be employed as protective bumpers for electronics or as grips on tools to enhance comfort and control. A study from the American Society of Mechanical Engineers indicates that incorporating rubber foot pads in design can reduce vibrations, further enhancing user experience and equipment longevity. The engagement of adhesive rubber feet not only streamlines various projects but also promotes safety and efficiency in both casual and professional settings.

Maintaining the longevity of adhesive rubber feet is essential for both home and industrial applications. According to a recent industry report by Grand View Research, the global market for rubber feet is projected to grow significantly, driven by increasing demand in furniture and machinery. To ensure these components remain effective over time, regular maintenance is critical. Keeping the surface clean, free from dust and grease, can prevent degradation and ensure optimal adhesion, prolonging their life span by up to 30%.

Environmental factors also play a crucial role in the durability of adhesive rubber feet. Data from the Rubber Manufacturers Association indicates that exposure to extreme temperatures and humidity can lead to deterioration. To combat this, users should consider relocating items with rubber feet away from direct sunlight and moisture-rich areas. Additionally, periodic inspection for signs of wear or damage can facilitate timely replacements, avoiding costly equipment failures. Implementing these maintenance strategies can significantly enhance performance and overall lifespan, ensuring that adhesive rubber feet continue to function effectively in diverse applications.