Customized solutions for rubber parts of aviation masks-SKY Rubber

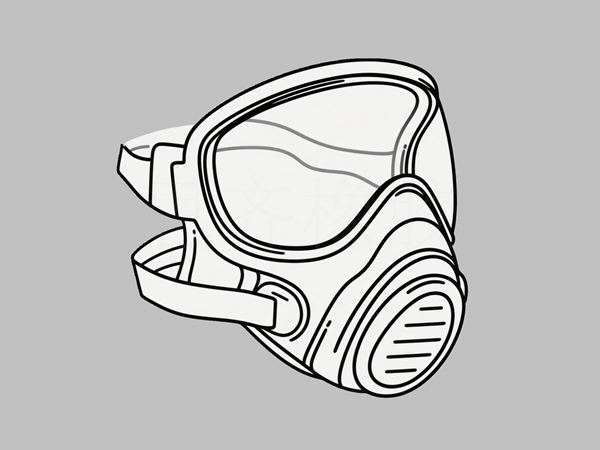

An aviation mask is an oxygen supply device that is equipped to respond to emergencies such as cabin depressurization when the aircraft is flying at high altitude. When the cabin pressure drops suddenly and the oxygen content is insufficient, the mask will automatically fall off from the overhead luggage rack or special cabin. Passengers need to quickly pull it down and wear it, and get oxygen through the connected oxygen generator to avoid loss of consciousness due to lack of oxygen, so as to buy time for the pilot to adjust the flight altitude or make an emergency landing. Its design is usually light and easy to operate, and it can provide personnel with necessary oxygen support in a short time. It is an important emergency equipment to ensure aviation safety.

An internationally renowned brand design companywith 17 years of creative design experience found us through the Internet when promoting the design of airline captain masks. The two sides successfully reached a cooperation. From mold design, manufacturing to proofing and assembly, it took only 15 days to complete a full set of samples, including various Plastic Parts, silicone parts, liquid silicone and plastic composite molded parts. This saves at least 15 days compared to ordinary liquid silicone production and sample preparation, greatly speeding up the project progress.

This aerospace design and production project is highly valued by the company. Under the leadership of General Manager Wu and Engineer Chen, the supply chain team collected information from many related production factories in and outside the province and compared them. They believed that our company's "SKY Rubber" has a very high cost-effectiveness in terms of production environment and quality control. Afterwards, the company's Vice President Liu personally led a team to inspect our production site and gain an in-depth understanding of the company's situation. He praised our on-site management and was impressed by our professional pre-sales, in-sales, and after-sales supporting service system. He finally decided to become a long-term partner with our company.

According to the company's design requirements, SKY Rubber needs to deliver a solid silicone aviation oxygen mask T0 sample within 10 days after the contract is placed. After fully understanding its design requirements, we took the initiative to suggest that the T0 sample, which was originally planned to be coated with solid silicone plastic, be changed to a liquid silicone coated plastic molding process. In this way, customers can experience a softer and skin-friendly touch when they get the T0 sample, without adding additional costs and time. After internal discussion, the company agreed to this change plan, and the re-set T0 sample delivery time was given to a maximum of 15 days, which was a very tight schedule. After the project was confirmed, the engineering center gave full play to the production advantages of the internal mold room, and each manufacturing process was carried out in an orderly manner, and finally the sample delivery was successfully completed within the 15-day delivery period.