Introduction to Butadiene Rubber (BR) -SKY RUBBER

Butadiene rubber, short for cis -1,4- polybutadiene rubber, has the molecular formula (C4H6)n . It is a structurally regular synthetic rubber polymerized from butadiene, with a cis structure content exceeding 95% .

Depending on the catalyst used, it can be classified into nickel-based, cobalt-based, titanium-based, and rare-earth (neodymium-based) butadiene rubbers.

Butadiene rubber is the second most widely used synthetic rubber after styrene-butadiene rubber (SBR). Compared to natural rubber and SBR, it exhibits superior cold resistance, abrasion resistance, and elasticity after vulcanization, generates less heat under dynamic loads, and has relatively good aging resistance. It is easily blended with natural rubber , chloroprene rubber, or nitrile rubber.

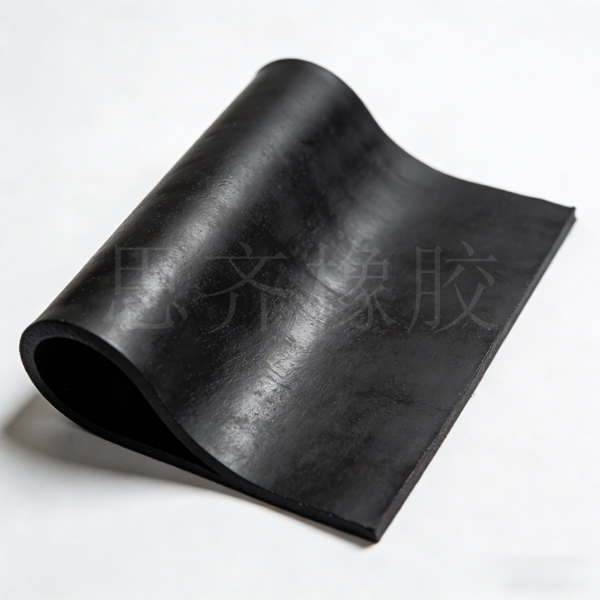

Butadiene rubber is particularly suitable for manufacturing automobile tires and cold-resistant products. It can also be used to manufacture cushioning materials, various rubber shoes, rubber sheets, tapes, and sponge rubber, etc.

Main applications : automobile tires, rubber hoses, rubber sheets, shoemaking, etc.

In China, butadiene rubber is mainly used in tires, footwear, high-impact polystyrene, and ABS resin modification. The demand from the tire manufacturing industry accounts for about 77% of the total demand , the footwear industry accounts for about 9% , the demand from plastic modification such as high-impact polystyrene and ABS resin accounts for about 10% , and the demand from other applications such as hoses and tapes accounts for about 4% .