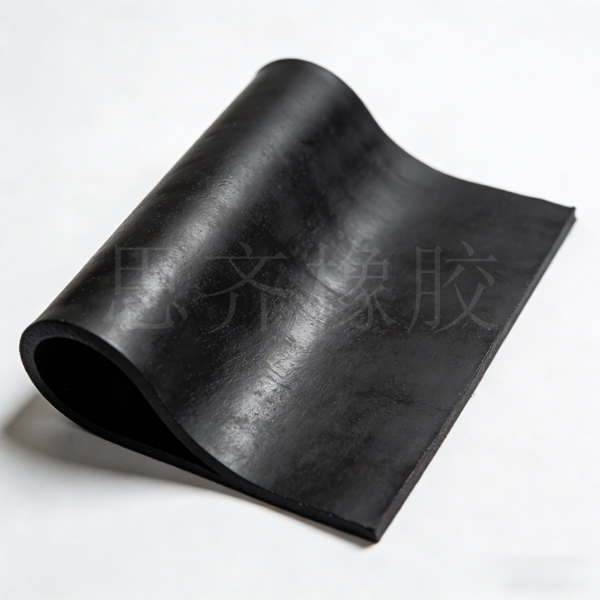

Introduction to Butyl Rubber (IIR) -SKY RUBBER

Butyl rubber, abbreviated as IIR , is an abbreviation for Isobutylene-Isoprene Rubber . It possesses excellent chemical and thermal stability, most notably its airtightness and watertightness. Its air permeability is only 1/7 that of natural rubber and 1/5 that of styrene-butadiene rubber , while its steam permeability is 1/200 that of natural rubber and 1/140 that of styrene-butadiene rubber. Therefore, it is mainly used in the manufacture of various inner tubes, steam pipes, water tires, dam bases, and gaskets, among other Rubber Products.

Performance characteristics :

advantage

It has good airtightness. It is also heat-resistant, ozone-resistant, aging-resistant, and chemical-resistant, and has shock-absorbing and electrical insulation properties. It has good resistance to sunlight and ozone and can be exposed to animal or vegetable oils or oxidizable chemicals.

shortcoming

The main disadvantages of butyl rubber include:

First, the vulcanization speed is slow. Compared with highly unsaturated rubbers such as natural rubber, its vulcanization speed is about three times slower, requiring high temperature or long time for vulcanization.

Second, it has poor mutual adhesion and requires the use of tackifiers and tackifying layers to improve its adhesion to other rubbers, and the adhesion strength is relatively low.

Third, it has poor compatibility with other rubbers and can generally only be used with ethylene propylene rubber and polyethylene, etc.

Fourth, the interaction with reinforcing agents is weak. Compared with unsaturated rubber, butyl rubber has a weaker interaction with reinforcing agents and requires heat treatment or the use of additives to increase the reinforcing effect of the rubber and improve tensile strength, tensile stress at a given elongation, elasticity, wear resistance and electrical insulation properties.

The above-mentioned disadvantages limit the applications of butyl rubber, and it is not recommended to use it simultaneously with petroleum solvents, kerosene, and aromatic hydrocarbons.

Main uses :

Butyl rubber (IIR ) is the world's fourth largest synthetic rubber ( SR ) type. It is a product of cationic polymerization of isobutylene and isoprene under Friedel-Craft catalyst. It appears as white or pale yellow crystals, odorless and tasteless, with a very low glass transition temperature, and is insoluble in ethanol and acetone. Due to its excellent airtightness and good heat resistance, aging resistance, acid and alkali resistance, ozone resistance, solvent resistance, electrical insulation, shock absorption, and low water absorption, butyl rubber is widely used in inner tubes, water tires, vulcanized bladders, airtight layers, tire sidewalls, wires and cables, waterproof building materials, shock-absorbing materials, pharmaceutical bottle stoppers, food (chewing gum base material), rubber dams, gas protective equipment, adhesives, inner tube valve cores, anti-corrosion products, dock and ship guardrails, bridge support pads, and heat-resistant conveyor belts.