Introduction to Chloroprene Rubber (CR) -SKY RUBBER

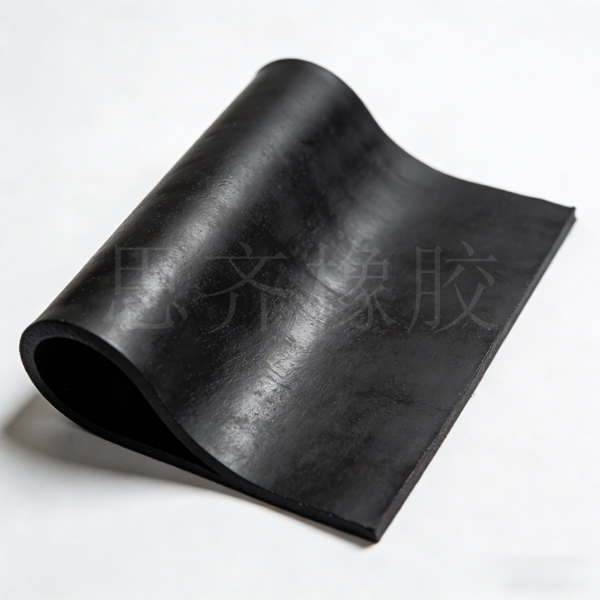

Chloroprene rubber is an elastomer made from chloroprene monomers through emulsion polymerization, coagulation, and drying. It was industrialized in 1931 , initially produced by DuPont in the United States. Global annual production is currently approximately 2 million tons.

Performance characteristics :

Advantages: It has excellent resistance to oxygen and ozone, is not flammable, can self-extinguish after ignition, is resistant to oil, solvents, acids and alkalis, as well as aging and has good air tightness; the physical and mechanical properties of general-purpose chloroprene rubber are close to those of natural rubber.

Disadvantages: It has poor cold resistance, a relatively high specific gravity, a relatively high cost, and poor electrical insulation.

Operating temperature range: approximately -35 to +130 ℃.

Main uses :

Based on its performance characteristics, chloroprene rubber is mainly used in flame-retardant products, oil-resistant products, weather-resistant products, and adhesives. Examples include waterproof building sheets, building sealing strips, highway joint sealants, bridge bearing gaskets, low-voltage wire and cable sheathing, various Sealing Products, anti-corrosion linings, and adhesives.

Chloroprene rubber is also widely used as an adhesive rubber.