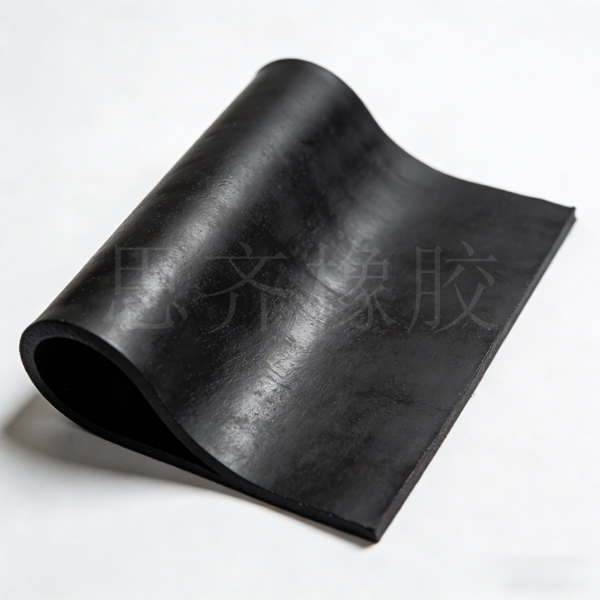

Introduction to Hydrogenated Nitrile Butadiene Rubber (HNBR) -SKYRUB

Because of the presence of double bonds in the main chain of NBR , its weather resistance, heat resistance, and chemical stability are poor, which limits its application range. Modified fully hydrogenated nitrile butadiene rubber ( HNBR ), partially hydrogenated nitrile butadiene rubber ( HSNBR ), XNBR , and thermoplastic NBR have all been commercialized, greatly improving their high temperature resistance, weather resistance, and ozone aging resistance.

HNBR exhibits significantly improved heat resistance while maintaining its oil resistance. Highly hydrogenated nitrile rubber demonstrates better heat resistance than acrylic rubber. However, with increasing hydrogenation, the rubber loses its elasticity at low temperatures.

Hydrogenated nitrile butadiene rubber ( HNBR ) is mainly used in fields that require extremely high weather resistance, media resistance, and mechanical stability, such as engine oil Seals, fuel lines, gearbox seals, oilfield extraction seals, oil hoses, diaphragms, aircraft hydraulic system seals, and fuel system components.