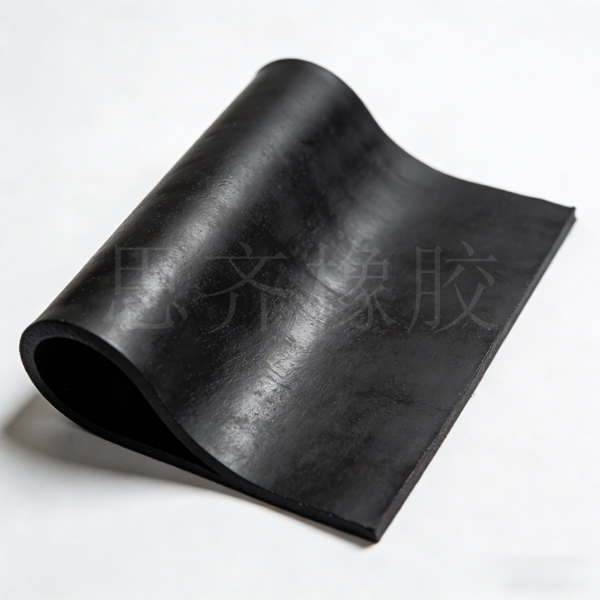

Introduction to Nitrile Butadiene Rubber (NBR) -SKY RUBBER

butadiene rubber (NBR) is a polymer formed by emulsion copolymerization of butadiene ( CH2=CH-CH=CH2 ) and acrylonitrile ( CH2=CH-CH-CN ), with an average molecular weight of around 700,000 . Rubber polymerized at 25 ℃ -50 ℃is called thermopolymerized NBR. NBR is renowned for its excellent oil resistance. Among existing rubbers, its oil resistance is second only to polysulfide rubber, acrylate rubber, and fluororubber, making it widely used in the Rubber Industry.

Performance characteristics :

It has excellent resistance to gasoline and aliphatic hydrocarbon oils, good heat resistance, good airtightness, wear resistance and water resistance, and strong adhesion.

Disadvantages: Poor cold and ozone resistance, low strength and elasticity, poor acid resistance, poor electrical insulation, and poor resistance to polar solvents.

Operating temperature range: approximately -30 to +130 ℃.

Main uses :

It is mainly used in oil-resistant products, such as various sealing products. Other applications include its use as a PVC modifier and in combination with PVC for flame-retardant products, in combination with phenolic resins for structural adhesives, and in Rubber Products with good antistatic properties.