Rubber Processing Technology - SKYRUB

Rubber processing involves multiple core procedures, each with significantly different operational objectives, processes, and safety risks. The following details the core content and safety points of each procedure in the order of the process flow:

- Raw Material Processing: Pretreatment to Ensure Subsequent Processes: Raw rubber is chopped and dried, while compounding agents are pretreated by crushing, screening, melting, filtering, and evaporation to provide qualified raw materials for subsequent batching, mixing and other processes.

- Ingredients: Precise weighing reduces dust hazards: According to the formula requirements, all kinds of raw rubber and compounding agents are precisely weighed and stored in special containers to prepare materials for the mixing process.

- Plasticizing and Thermal Refining: Adjusting the Plasticity of Rubber Compounds

Plasticizing: The key process of converting elastic raw rubber into a plastic state. It is usually carried out on an open mill or internal mixer. Through mechanical action, the rubber macromolecules are broken down, reducing hardness and increasing plasticity to meet the needs of subsequent processing.

Hot refining: The processing object is the rubber sheet that has been mixed and then left to rest. It is mainly operated on a two-roll mill. The principle is similar to plasticizing . The purpose is to further adjust the plasticity of the rubber sheet so that it can be used in subsequent processes.

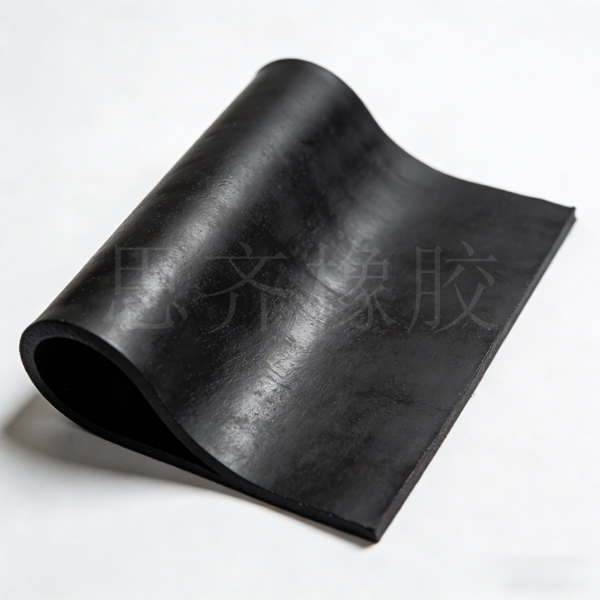

- Mixing: Achieving uniform dispersion of compounding agents: On an open or closed rubber mixing mill, the plasticized rubber compound is thoroughly mixed with various compounding agents to ensure that the compounding agents are uniformly dispersed in the rubber compound. Finally, it is pressed into mixed rubber sheets by a sheeting machine.

- Calendering: Rubber compound forming and bonding: Through the Extrusion action of the calender rollers, the rubber compound is pressed into a sheet of a specific thickness, or the sheet is bonded to the textile, or the adhesive is applied /coated to the surface of the textile.

- Extrusion: Semi-finished product molding: The extrusion force generated by the rotation of the extruder screw pushes the rubber material in the barrel forward along the spiral groove. At the same time, the rubber material is further plasticized and mixed by the shearing action between the screw ribs and the inner wall of the barrel. Finally, with the help of the die head and mandrel, rubber semi-finished products with different cross-sectional shapes are extruded to achieve preliminary or final molding.

- Dipping: Adhesive adhesion treatment: Various models or textiles are immersed in adhesive and repeatedly dipped to make the adhesive adhere evenly to the surface, thereby improving product performance (such as waterproofing and abrasion resistance).

- Preparation of Adhesive (Pulping): A key process with flammable risks: Also known as pulping, solvent gasoline is added to raw rubber or compound rubber, placed in a sealed container with a stirrer, and continuously stirred to make adhesive.

- Applying adhesive: Apply adhesive paste evenly to the surface of the textile using manual or mechanical methods to form a functional coating.

- Oil boiling, oil rinsing, and varnishing: Preparation and application of varnishing agents:

Oil rendering: Using open flame heating to prepare the basic raw materials for polishing agents;

A polishing agent prepared using gasoline as a raw material in an environment below 25°C;

Varnishing: An open-application process in which a varnishing agent is applied to the surface of the product to enhance its appearance and protective properties.

- Molding: Pre-finished product processing: Processing various raw materials or semi-finished products into pre-finished products of specific shapes. Most pre-finished products need to be vulcanized to become the final product; a few thermoplastic Rubber Products do not require vulcanization and can be used directly after molding. Common molding equipment includes tire molding machines, cord bonding machines, and hose winding machines.

- Vulcanization: A key process for improving rubber performance: Under the action of an accelerator, the vulcanizing agent and rubber react at a specific temperature and pressure for a certain period of time. Through chemical and physical reactions, the rubber molecules are transformed from a linear structure to a network cross-linked structure. Vulcanized rubber products exhibit significantly improved strength and also achieve excellent elasticity, abrasion resistance, and other performance properties.